Box Plant Basics – Box Plant Equipment Basics

This course introduces some common box plant equipment and processes, and discusses equipment layout, material flows, and storage considerations in box plants.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Introduction to corrugated fiberboard • Box plant processes • Box plant categories • Descriptions of typical box plant equipment • Equipment layout considerations

Specs

Frequently Asked Questions

What does a corrugator do?

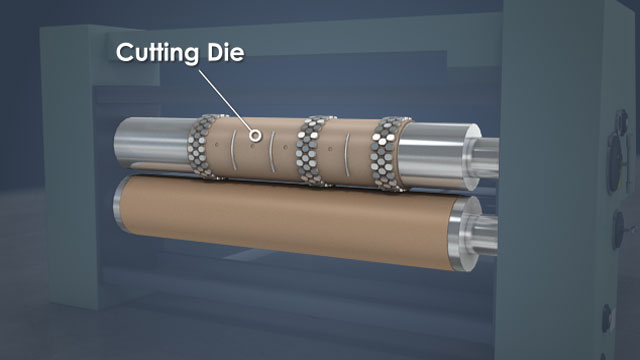

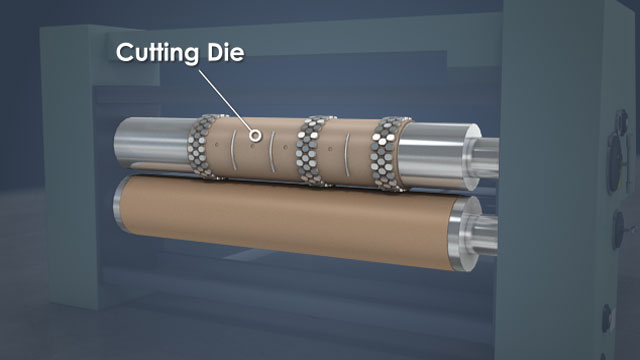

How are the sheets of corrugated board produced on a corrugator made into box blanks?

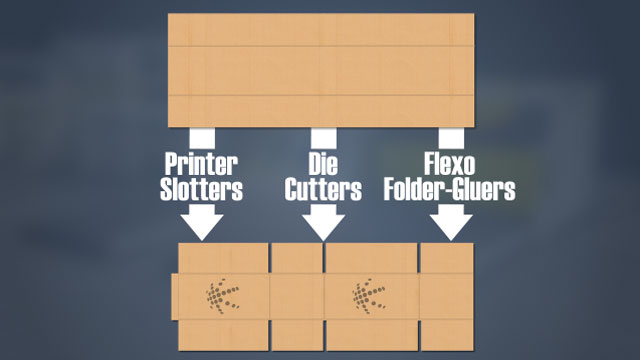

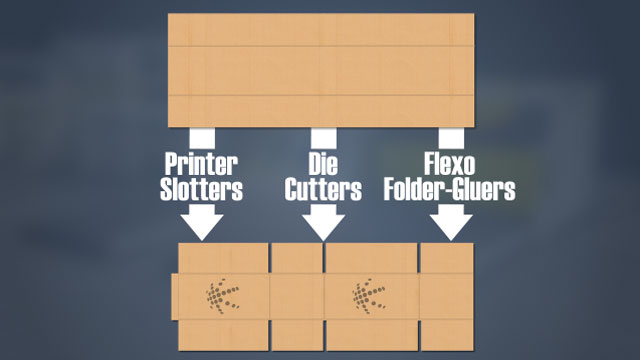

What converting machines are used to produce box blanks?

What is considered when deciding upon the equipment layout for a new box plant?

Why is it important to maintain adequate space around the equipment in box plants?

Sample Video Transcript

To convert a piece of corrugated fiberboard into a box, the board must be cut, slotted, and scored into a box blank, the precursor to a box. Many boxes are also printed, folded, and glued before they are shipped to the customer. And some boxes are stitched, taped, or labeled or have specialty forms and materials inserted before they leave the box plant. Some common pieces of equipment that can be found at a box plant are listed next. It is important to keep in mind that every box plant is different. A very small box plant can have a single flexo-folder-gluer, while a very large box plant can have dozens of different machines.