April 3, 2024 7 min read

Oil and Gas Safety: Top Hazards and Solutions

Industry:

Solution:

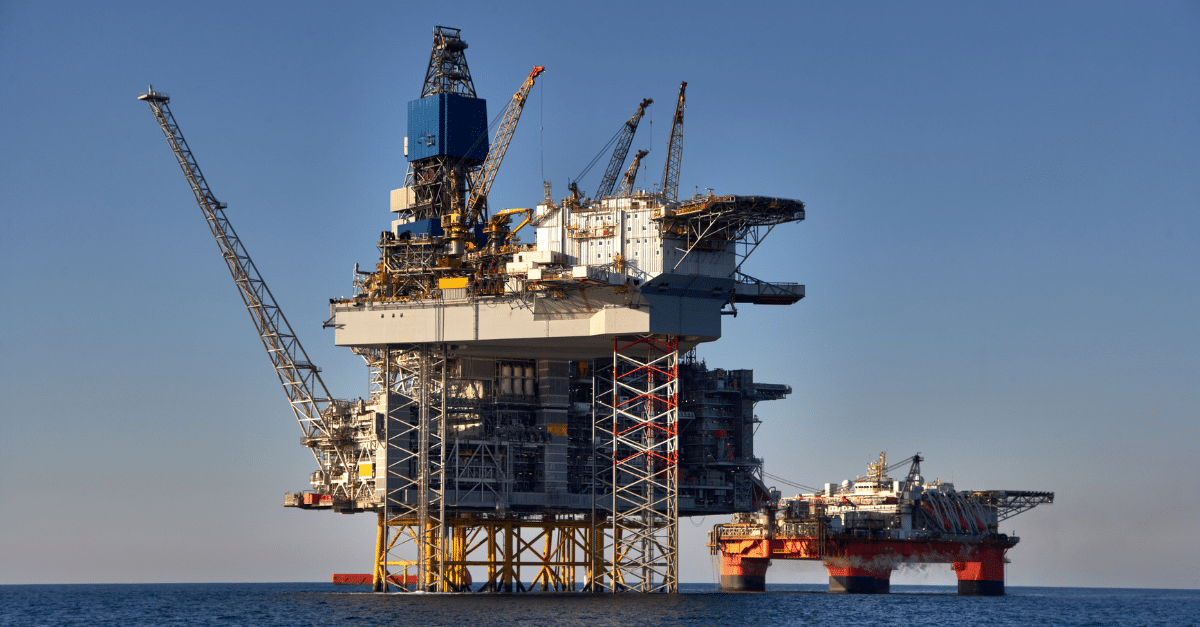

The Oil and Gas industry is undoubtedly one of the most vital sectors powering the global economy, providing the energy resources essential for transportation, manufacturing, and countless other activities. However, the nature of oil and gas operations also presents inherent risks and hazards that demand meticulous attention to safety. In this blog, we’ll review the top oil and gas safety hazards and solutions your organization can use to mitigate risk and prevent incidents.

An Introduction to Oil and Gas Safety

Safety practices in the oil and gas industry are a fundamental requirement for protecting personnel, preserving the environment, and ensuring operational integrity.

With operations spanning exploration, drilling, production, transportation, and refining, workers in this industry encounter many hazards daily. From working in remote and harsh environments to handling volatile substances and operating heavy machinery, the challenges are diverse and complex.

Online Safety Training Courses

In-depth safety training based on OSHA & EPA requirements and general best practices that helps put your learners “on location” and ready to identify and address hazardous condition

Explore Courses

The Consequences of Safety Incidents

Safety incidents can have severe consequences, ranging from loss of life and injuries to environmental damage, property destruction, and financial losses. These incidents not only impact individuals but also have broader repercussions on communities, ecosystems, and organizational reputation.

Recognizing these risks, stakeholders across the Oil and Gas sector are continually striving to enhance safety performance and prevent accidents through proactive measures and innovative solutions.

Is Oil and Gas a High-Risk Industry?

The oil and gas industry is considered one of the highest risk industries as far as environmental impacts and employee safety is concerned.

This is due to a variety of factors:

- Fossil fuel production has an impact on global warming and air quality

- Cyber threats targeting the energy sector have increased (39% of all cyber infrastructure attacks impact this sector)

- Natural disasters and other catastrophic events (e.g., oil rig spills, fires, etc.)

- Increased work site hazards, including chemical exposure/management

- High levels of employee turnover and difficulty to attract talent

What Are Common Oil and Gas Safety Hazards?

There are many potential safety hazards in the oil and gas industry. From exploration to production, transportation, and refining, workers face numerous risks that demand constant vigilance and proactive mitigation strategies.

Here are some of the main safety hazards to consider when creating your safety training plan:

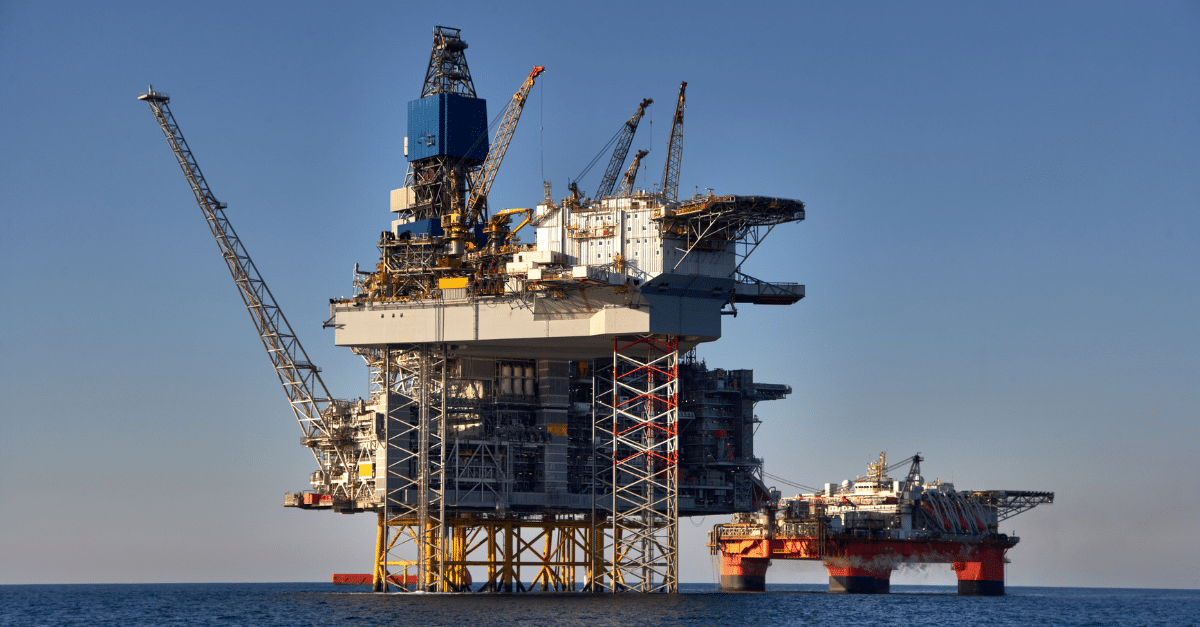

1. Workplace Safety Hazards

Oil and Gas facilities, including drilling rigs, refineries, and pipelines, are complex and dynamic work environments. Workers may be exposed to various physical hazards, including:

- Slips, trips, and falls

- Working at heights; falls

- Working in confined spaces

- Heavy equipment and machinery

- Heat stress

Failure to implement proper safety protocols can result in serious injuries or fatalities.

2. Process Safety Hazards

The handling and processing of hazardous substances, such as crude oil, natural gas, and chemical additives, pose significant risks.

These hazards encompass the risk of fires, explosions, toxic releases, and environmental pollution. Incidents involving these hazardous substances and chemicals can endanger both personnel, environments, and surrounding communities.

3. Environmental Hazards

Oil and gas operations have the potential to cause significant environmental harm, including soil and water contamination, air pollution, and habitat destruction. Spills, leaks, and emissions from drilling, extraction, transportation, and storage activities can result in long-term ecological damage and regulatory compliance challenges.

Mitigating environmental hazards requires robust risk management practices and adherence to stringent regulatory requirements.

4. Transportation Hazards

Transportation-related activities, such as the movement of personnel, equipment, and hazardous materials via road, rail, or marine vessels, present inherent risks to workers. Collisions, rollovers, and spills during transportation can lead to injuries, fatalities, and environmental incidents.

Additionally, transporting flammable substances increases the potential for fires and explosions, necessitating comprehensive safety protocols and training for drivers and operators.

Learn more about our transportation safety and compliance training!

5. Health Hazards

Workers may be exposed to various health hazards, including chemical exposures, ergonomic stressors, noise, and vibration. Prolonged exposure to these hazards can result in occupational illnesses such as respiratory disorders, dermatitis, musculoskeletal injuries, and hearing loss.

Effective hazard identification, exposure monitoring, and preventive measures are essential to safeguarding workers’ health and well-being.

6. Human Error

Factors such as fatigue, inadequate training, complacency, and communication breakdowns can compromise safety performance and lead to accidents. Addressing human factors requires comprehensive training programs, effective supervision, and a safety culture that encourages open communication, situational awareness, and continuous improvement.

Oil and Gas Safety Statistics

Oil and gas safety must be taken seriously.

In 2022, the oil and gas industry had an average injury and illness rate of 1.8 per 100 workers. This increased compared to the previous year due to increased exploration and production.

Between 2013 and 2017, 489 oil and gas extraction workers were killed on the job. The CDC has reported that fatalities in oil and gas extraction are primarily caused by:

- Vehicle incidents (26.8%)

- Contact injuries (21.7%)

- Explosions (14.5%)

Prioritizing proper training, communication, incident reporting, and safety management can help keep workers in high-risk industries safe from harm and illness.

Oil and Gas Safety Solutions

Considering the significant safety hazards present in the oil and gas industry, proactive measures and effective safety solutions must be put in place.

Oil and Gas Safety Training

Comprehensive training is one of the most important steps you can take. This builds a foundation of knowledge, skills, and awareness that helps industry workers identify hazards, comply with mandatory safety procedures, and respond appropriately in emergencies.

Key types of training required to keep oil and gas workers safe include:

- Hazard Awareness Training. Educating workers about the specific hazards they may encounter in their roles, including workplace hazards, process safety risks, environmental concerns, and health hazards.

- Skills-Specific Safety Training. Providing hands-on training on the safe operation of equipment and machinery, proper use of personal protective equipment (PPE), and adherence to safety protocols during routine tasks and emergency situations.

- Emergency Response Training. Conducting drills and simulations to prepare workers for responding to incidents such as fires, explosions, spills, and medical emergencies, ensuring they can take prompt and effective action to mitigate risks and protect themselves and others.

- Regulatory Compliance Training. Ensuring workers are aware of relevant regulations, standards, and industry best practices governing safety (e.g., OSHA, EPA).

EHS Management for Oil and Gas

Effective Environmental, Health, and Safety (EHS) management is essential for mitigating risks, ensuring regulatory compliance, and driving continuous improvement in oil and gas safety.

A robust EHS management system, like Vector EHS, encompasses various elements, including:

- Incident and OSHA-compliant Reporting

- Inspections and safety audits

- Real-time metrics (e.g., DART rate, total recordable incident rate (TRIR))

- Behavior-based safety and job safety analysis

- Hazard reporting

- SDS management

Vector EHS Management Brochure

Bring all your organization’s EHS activities, tasks, and reports into one single, easy-to-use solution to gain visibility into the data and trends needed to shift from a reactive to a proactive safety culture

Learn More

Why Choose Vector Solutions to Improve Oil and Gas Safety

Vector Solutions offers tailored safety training and management solutions designed to meet the unique needs of the Oil and Gas industry.

With deep knowledge and experience, we understand the specific safety challenges facing the oil and gas sector. We use that knowledge to create award-winning eLearning courses to fill skills gaps, increase safety, and help improve employee retention.

“[Vector Solutions] gives us the ability to create consistent training experiences for our employees and the ability to deliver those effectively every time—that’s priceless.”

— Training Analyst

If you want to see any of our solutions in action, request a demo today.