March 6, 2024 4 min read

What is an MSDS or SDS? Is there a difference?

Industry:

Solution:

It’s no secret that there are numerous hazardous chemicals in workplaces that can be dangerous to a worker’s health and safety. That’s why the Occupational Safety and Health Administration (OSHA) developed its Hazard Communication (HAZCOM) Standard to easily communicate the potential dangers of a chemical to its workers.

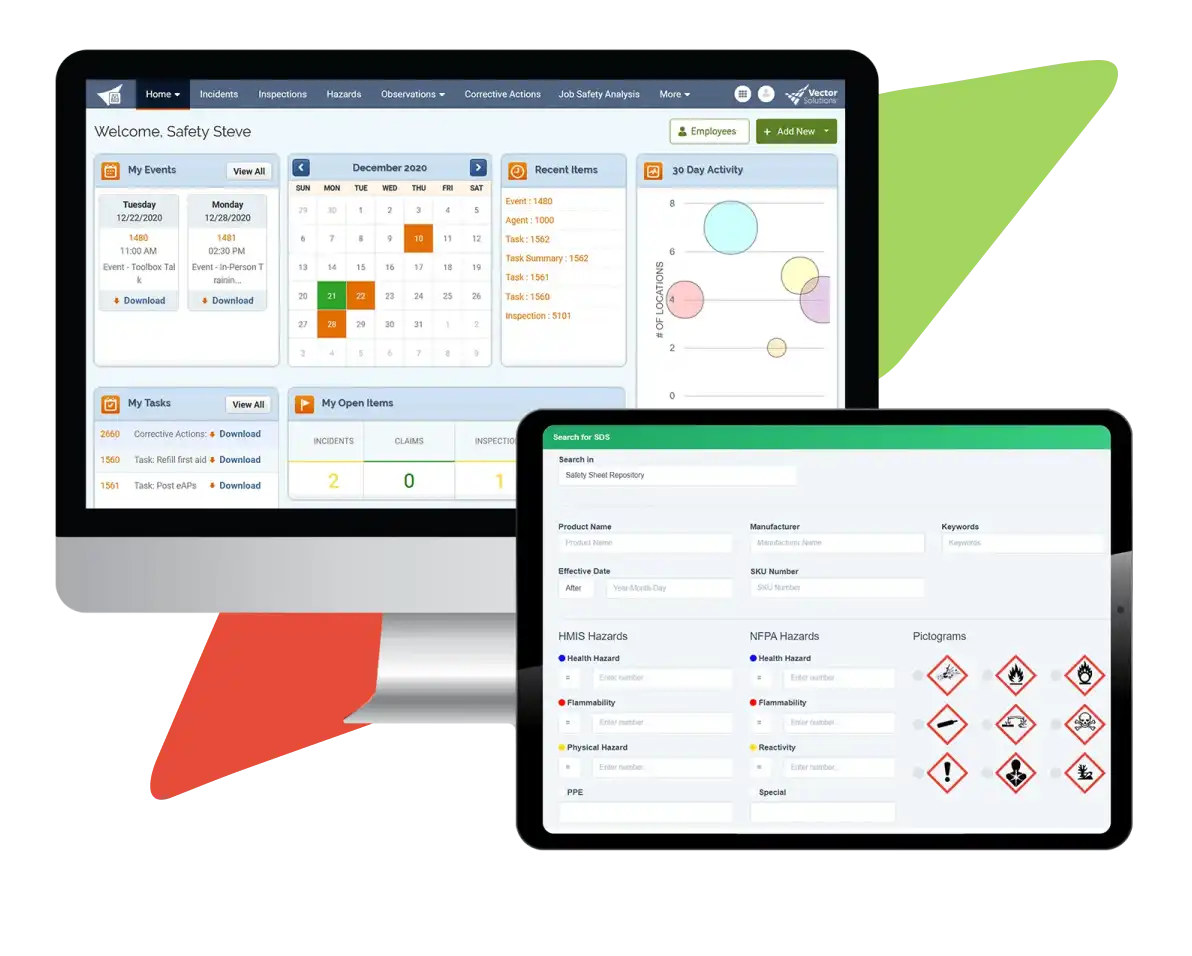

Part of the HAZCOM Standard requires organizations to have safety data sheets (SDS) for each hazardous material and chemical that could be encountered in the workplace. A safety data sheet (formally known as Material Safety Data Sheets or MSDS) is a document to summarize important health and safety information for hazardous chemicals.

SDS Management Software Buyer’s Guide

This guide is designed for you to use in your search for the safety data sheet management solution that works best for you and your company

Download Guide

What is an SDS?

SDS stands for Safety Data Sheet, which is a comprehensive document that provides crucial information about the hazards of chemicals, as well as safety precautions for their handling, storage, and disposal.

SDSs are essential for workplace safety and compliance with regulations, ensuring that workers, emergency responders, and other stakeholders have access to critical information to handle chemicals safely and effectively.

What information is on an SDS?

Safety data sheets are designed to effectively communicate the potential hazards associated with each chemical encountered by employees. SDS information includes the properties of each chemical, all potential hazards and protective measures, and precautions for the safe transporting, handling, and storage of the chemical.

The minimum information that must be included in an SDS is listed in Appendix D of OSHA’s Hazard Communication Standard (HAZCOM). It is also important to know that, while other languages are allowed, each SDS must have a copy in English.

Adhering to the UN Globally Harmonized System of Classification and Labeling of Chemicals (GHS) ensures consistency and facilitates easy access to essential information across different regions and industries. This means all safety data sheets must follow the same 16 section format, making it easy to search for specific information. Below are the 16 sections of an SDS:

- Identification

- Hazard(s) Identification

- Composition/Information on Ingredients

- First-aid Measures

- Fire-fighting Measures

- Accidental Release Measures

- Handling and Storage

- Exposure Controls/Personal Protection

- Physical and Chemical Properties

- Stability and Reactivity

- Toxicological Information

- Ecological Information (Non-Mandatory)

- Disposal Considerations (Non-Mandatory)

- Transport Information (Non-Mandatory)

- Regulatory Information (Non-Mandatory)

- Other Information, including date of preparation or last revision

What is an MSDS?

MSDS stands for Material Safety Data Sheet. Much like an SDS, it is a document that provides detailed information about the potential hazards of a chemical product, as well as instructions for its safe handling, storage, and disposal.

MSDSs were commonly used before the adoption of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), which led to the transition to Safety Data Sheets for standardized hazard communication.

What is the difference between MSDS vs SDS?

The main difference between an MSDS and an SDS is the standardized formatting. All SDSs follow the GHS’s 16 section formatting, while MSDSs could come in many different formats depending on the organization. Beyond that, they aim to convey the same information regarding chemical hazards.

By regulating MSDSs in accordance with the GHS, it is now simpler and easier to find common hazard safety information with SDSs. As of June 1, 2015, all MSDSs should have been converted into SDS format. However, old habits die hard, so if you hear someone refer to an MSDS, you know they are really talking about an SDS.

Health, Safety & Environment (HSE) Premium Online Training Library

Complete with powerful 3D animations and models, these interactive online safety training courses address common hazardous situations faced in a variety of environments and industries.

Download Now