February 23, 2018 4 min read

How to inspect an aerial lift to meet OSHA requirements

Industry:

Solution:

The Occupational Safety and Health administration (OSHA) lists requirements you must follow to ensure worker safety when operating an aerial lift. Part of these requirements is to inspect the vehicle and lift components before actually using the aerial lift.

This article will help you keep workers safe while operating aerial lifts by summarizing OSHA’s aerial lift inspection requirements and how to inspect an aerial lift. It also provides additional resources such as safety inspection software that will make your job easier.

OSHA Aerial Lift Requirements

The mobility and flexibility of aerial lifts to elevate individuals have made them convenient tools in the workplace especially when ladders cannot be used safely. However, aerial lifts can be quite dangerous if not properly operated.

OSHA Standard 1926.453 lists specific requirements for an aerial lift to be in safe operating condition. In addition to the pre-use inspection (more on that below), we recommend you turn this list of aerial lift requirements into a safety inspection to confirm whether or not these regulations are being followed.

For example, check to make sure only authorized people will be operating the lift. You’ll also want to verify a body belt and lanyard are attached to the basket when working from an aerial lift.

OSHA’s standards also list several actions and items that should not occur to keep an eye out for. This includes not moving the aerial lift truck when the boom is elevated, and not exceeding the boom and basket load limits specified by the manufacturer.

Using an aerial lift inspection checklist based off of OSHA’s Aerial Lifts Standard is the easiest way to comply with the regulation. It will not only help ensure worker safety, but also help you avoid any fines for violating safety regulations in the event of an OSHA inspection.

Aerial Lift Pre-Use Inspection

One of OSHA’s requirements that sticks out is that lift controls shall be tested each day prior to use to determine that such controls are in safe working condition. This is known as a pre-start inspection.

Prior to each work shift, a pre-start inspection should be conducted to ensure the aerial lift is in safe operating condition. During this in-depth check, OSHA recommends looking over the following parts of the vehicle:

Vehicle Components

- Lower-level controls

- Battery and charger

- Wheels and tires

- Steering and breaks

- Horn, lights and backup alarms

- Proper fluid levels (oil, hydraulic, fuel and coolant)

Some issues such as a flat tire may be obvious, but other issues such as dim lights may be up to a judgement call of the inspector. You can either check the manufacturer’s recommendations, or simply err on the side of caution to avoid any potential safety issues.

Keep in mind that inspecting the proper fluid levels includes both ensuring the levels aren’t too low, as well as no signs of leakage.

Lift Components

Part of the pre-start inspection also includes inspecting the lift itself. That means reporting any hazards related to:

- Operating and emergency controls

- Hydraulic, pneumatic, electrical, fuel and air systems

- Fiberglass and other insulating parts

- Mechanical fasteners and locking pins

- Cable and wiring harnesses

- Any loose or missing parts

If any of the parts of either the lift or vehicle appear defective, do not operate the aerial lift. Remove the defective lift from service until repairs are made by a qualified person.

Part of OSHA’s aerial lift requirements specify that all aerial lifts in-use must comply with the American National Standards for “Vehicle Mounted Elevating and Rotating Work Platforms”, also known as ANSI A92.2-1969. Keep this in when using an older aerial lift, or when shopping for a new one.

Bonus Tip: Save Time using an Inspection Software

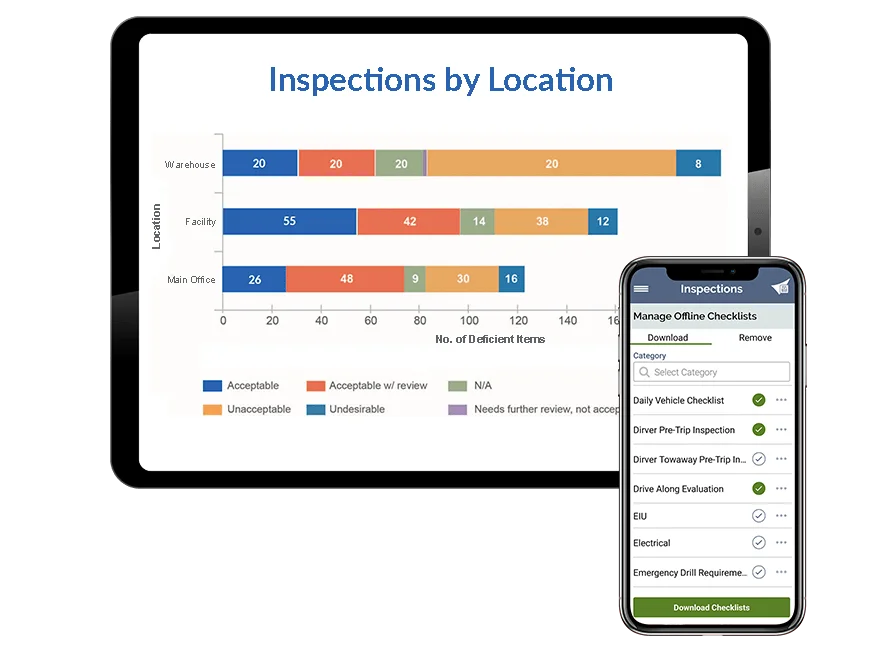

You may also want to consider downloading Vector EHS Management Software’s mobile app to record your inspection findings. This EHS management software will enable you to use pre-built checklists based on OSHA regulations (including its aerial lift requirements). You can also create your own checklists based off your company’s needs.

Vector EHS Management’s inspection mobile app will also let you upload pictures of defective items and work with or without internet access. To test out the Vector EHS mobile app and see if it’s a fit for you, sign up for a free demo account before downloading it in either the App Store® or Google Play™.