May 6, 2024 6 min read

Loading Dock Safety Tips: Protecting Workers and Preventing Accidents

Industry:

Solution:

Loading docks are crucial to fulfilling customer expectations in industries such as shipping, logistics, warehousing, transportation, distribution centers, and manufacturing. In fact, specific to transportation, the Bureau of Transportation reported the U.S. transportation system moved a daily average of about 53.6 million tons of freight valued at more than $54 billion in 2021. While loading docks provide the means for a smooth flow of goods, they also present significant safety hazards that must be addressed to protect workers and prevent accidents. Keep reading to get expert loading dock safety tips to keep your workforce safe.

5 Loading Dock Safety Tips

Navigating loading dock environments demands a keen eye for safety. From proper training to proactive measures, ensuring the well-being of workers and preventing accidents is paramount. These loading dock safety tips will help you reduce safety risks and increase hazard awareness.

- Proper Training: All workers involved in loading dock operations should receive thorough training on safety procedures, equipment usage, and hazard recognition.

- Clear Communication: Effective communication between dock workers, truck drivers, and supervisors is essential to ensure everyone is aware of their roles and responsibilities.

- Regular Inspections: Loading dock equipment, such as dock levelers, bumpers, lights, and forklifts should be inspected regularly to identify and address issues promptly.

- Safe Loading and Unloading Procedures: Workers should follow proper techniques when loading and unloading goods to minimize the risk of injuries, such as using hand trucks, pallet jacks, and forklifts safely.

- Fall Prevention: Guardrails, dock safety gates, and harnesses should be used to prevent falls from loading docks or trucks. Fall Protection is also number one on OSHA’s top ten most-cited safety violations list.

New Course Spotlight: Warehouse and Loading Dock Safety

In less than an hour, provide your team with invaluable insights into navigating the hazards of warehouse docks and loading docks. From personal protective equipment to emergency procedures, equip your warehouse and dock workers, forklift operators, material handlers, and more with the knowledge they need to stay safe in high-risk environments

View Course

Common Causes of Injury at Loading Docks

One of the most common causes of injury at loading docks is slips, trips, and falls. These accidents can occur due to:

- Wet or slippery surfaces.

- Uneven or damaged flooring.

- Improper use of equipment, such as forklifts or pallet jacks.

- Inadequate lighting or visibility.

Loading Dock Safety Precautions

Maintaining a safe environment at loading docks requires a strategic combination of precautionary measures. Some essential safety precautions employed in distribution docks and warehouse docks to mitigate risks and ensure the well-being of workers include:

- Dock Locks and Chocks: Wheel chocks and dock locks prevent trailers from moving during loading and unloading, reducing the risk of accidents.

- Dock Levelers: Properly functioning dock levelers ensure smooth transitions between the dock and the trailer, preventing tripping hazards.

- Lighting: Adequate lighting at loading docks improves visibility and helps workers identify potential hazards.

- Personal Protective Equipment (PPE): Workers should wear appropriate PPE, such as steel-toed boots, high-visibility vests, and hard hats, to protect themselves from injuries.

OSHA Rules for Loading Docks

The OSHA has specific regulations that apply to loading dock safety and loading dock fall protection when near exposed dock doors or openings. Key requirements include:

- Ensuring that dockboards or bridge plates are in good condition and secured in place.

- Providing adequate lighting and ventilation in loading areas.

- Implementing measures to prevent falls, such as guardrails or harnesses.

- Training workers on safe loading and unloading practices and the use of equipment.

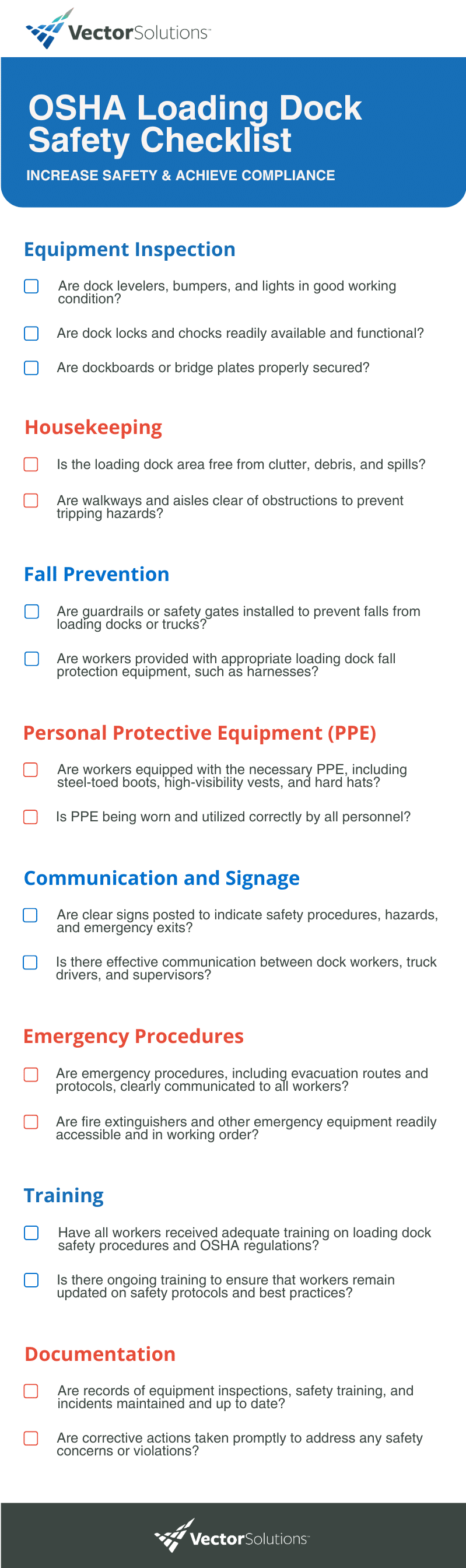

OSHA Loading Dock Safety Checklist

Ensuring compliance with OSHA regulations is essential for maintaining a safe working environment at loading docks. Here’s a brief checklist to help you assess loading dock safety measures:

✔ Equipment Inspection:

- Are dock levelers, bumpers, and lights in good working condition?

- Are dock locks and chocks readily available and functional?

- Are dockboards or bridge plates properly secured?

✔ Housekeeping:

- Is the loading dock area free from clutter, debris, and spills?

- Are walkways and aisles clear of obstructions to prevent tripping hazards?

✔ Fall Prevention:

- Are guardrails or safety gates installed to prevent falls from loading docks or trucks?

- Are workers provided with appropriate loading dock fall protection equipment, such as harnesses?

✔ Personal Protective Equipment (PPE):

- Are workers equipped with the necessary PPE, including steel-toed boots, high-visibility vests, and hard hats?

- Is PPE being worn and utilized correctly by all personnel?

✔ Communication and Signage:

- Are clear signs posted to indicate safety procedures, hazards, and emergency exits?

- Is there effective communication between dock workers, truck drivers, and supervisors?

✔ Emergency Procedures:

- Are emergency procedures, including evacuation routes and protocols, clearly communicated to all workers?

- Are fire extinguishers and other emergency equipment readily accessible and in working order?

✔ Training:

- Have all workers received adequate training on loading dock safety procedures and OSHA regulations?

- Is there ongoing training to ensure that workers remain updated on safety protocols and best practices?

✔ Documentation:

- Are records of equipment inspections, safety training, and incidents maintained and up to date?

- Are corrective actions taken promptly to address any safety concerns or violations?

Regularly reviewing and updating your loading dock safety checklist in accordance with OSHA guidelines is crucial for maintaining a safe and compliant workplace. By prioritizing safety and adhering to best practices, you can minimize risks and protect the well-being of your workforce.

Implementing Online Safety Training for your Loading Dock Workers

To ensure that workers receive comprehensive training in loading dock safety, online training courses can be highly beneficial and delivered quickly. Organizations find eLearning courses, developed by subject matter experts, provide the organization opportunities to align training with the latest OSHA and DOT standards, while raising awareness across the workforce to specific hazards of loading dock operations.

“Vector gives us the ability to create consistent training experiences for our employees and the ability to deliver those effectively every time—that’s priceless.”

—Training Analyst, Industrial Manufacturer

By providing accessible and interactive online training and learning management, employers can empower their workers with the knowledge and skills needed to prevent accidents and promote a culture of safety in the workplace.

Ready to experience the power of industry-specific training for your loading dock workforce? Connect with one of our experts today and together let’s empower your team to navigate loading dock challenges with confidence and expertise.

Prioritizing Loading Dock Safety

Loading docks work environments require careful attention to safety to protect workers and prevent accidents. By implementing best practices, adhering to loading dock safety tips and precautions, following OSHA regulations, and providing comprehensive online training, businesses can create safer working conditions and reduce the risk of injuries at loading docks. Prioritizing loading dock safety not only protects workers but also contributes to improved productivity and efficiency in operations.

Connect with us today to learn more about implementing a comprehensive health and safety training program.