June 11, 2018 4 min read

3 Tips to Meet OSHA Forklift Inspection Requirements

Industry:

Solution:

The Occupational Safety and Health Administration (OSHA) has developed a set of standards for the inspection of forklifts and powered industrial trucks (PITs) to ensure worker safety. A proper forklift inspection involves conducting a visual check, an operating inspection, and documenting all inspections (preferably through safety inspection software).

Vector EHS Management Software empowers organizations – from global leaders to local businesses – to improve workplace safety and comply with environmental, health, and safety regulations.

Learn more about how our software can save you valuable time and effort in recording, tracking, and analyzing your EHS activities.

Learn more about how we can help:

- Incident Management Software →

- EHS Inspection Software →

- Key Safety Metrics Dashboard →

- Learning Management System (LMS) and Online Training Courses →

- Mobile Risk Communication Platform

Download our EHS Management Software Buyer’s Guide.

OSHA estimates that each year forklifts account for approximately 100,000 industrial injuries. One-third of these injuries are deemed serious, meaning they resulted in an employee missing or restricted work.

With this in mind, OSHA developed a comprehensive set of safety training requirements for forklift operation and maintenance that all organizations must follow.

While these are not the most complex of OSHA’s many health and safety standards, the requirements contained in the PIT standard are often the subject of OSHA citations and can expose an employer to potential criminal liability if they are not followed. That’s why we’ve developed this article to take the guesswork out of how to perform a proper forklift inspection.

To maintain a safe environment when operating a forklift, you can implement and comply with the following requirements, and best practices:

1) Conducting a visual check

OSHA requires that all forklifts be examined at least daily before they are used to ensure that they’re in safe operating condition. If forklifts are used on a round-the-clock basis, then they must be examined after each shift.

When conducting a forklift inspection, you should first perform a pre-start visual check with the engine off. This is similar to a pre-start aerial lift inspection, in that you will be scanning the machine for potential issues.

Be sure to check the fluid levels for oil, water, and hydraulic fluid, as well as any leaks, cracks or other visible defects. This is common for most industrial vehicles, as OSHA’s crane inspection requirements also include these checks.

You should also test the chain tension in the mast using a stick or similar device. Do NOT place your hands inside the mast!

Next, test the tire pressure while keeping an eye out for cuts and gouges. From there move on to testing the condition of the forks, including the top clip retaining pin and heel, in addition to the load backrest extension, and finger guards.

Afterwards, check the safety decals and nameplates, making sure they are all in place and legible. This extends to the operator manual, which also needs to be kept on board the forklift.

Finally, check the operator compartment for grease, debris, and other anomalies. This final part of the pre-start inspection involves ensuring all safety devices are working properly, including the seat belt.

A forklift in need of repair, defective, or in any way unsafe, should not be driven and should be taken out of service immediately. Any problems should be recorded and reported to a supervisor. It’s critical to let workers know that they will not be able to use the forklift until it is fully repaired.

2) Performing an operating inspection

Once the visual check is completed, operators should conduct an operational inspection while the engine is running.

Evaluate the accelerator linkage, inch control if equipped, breaks, and steering. Is the steering hard to turn or loose? If so, that should be noted.

It is equally important to test the drive control, tilt control, both forward and back, and the hoist and lowering control. Don’t forget checks on the horn, lights, and back-up alarm if equipped.

If at any point you hear unusual noises or feel unusual vibrations, this should be reported immediately and work should be stopped. These unusual noises or vibrations can even be caused by not following safe stacking guidelines, which can cause other types of risk that are just as dangerous as a malfunctioning forklift.

Otherwise, if your inspection concludes that nothing appears to be malfunctioning, your employees should be able to operate the forklift.

3) Execute and document these inspections frequently

While OSHA does not require that forklift inspections be documented, it is recommended you record your findings using an inspection checklist. This way in the event of an OSHA inspection, you provide evidence that forklifts are being inspected as required. This will be critical in the event an incident occurs while the forklift is in operation.

Because forklift inspections are required daily, it is also important to know how to carry out such inspections. If an operator is unaware of a condition that would require a forklift to be put out of service, the consequences could be disastrous. Proper forklift safety training can ensure operators know what to look for when conducting a forklift inspection.

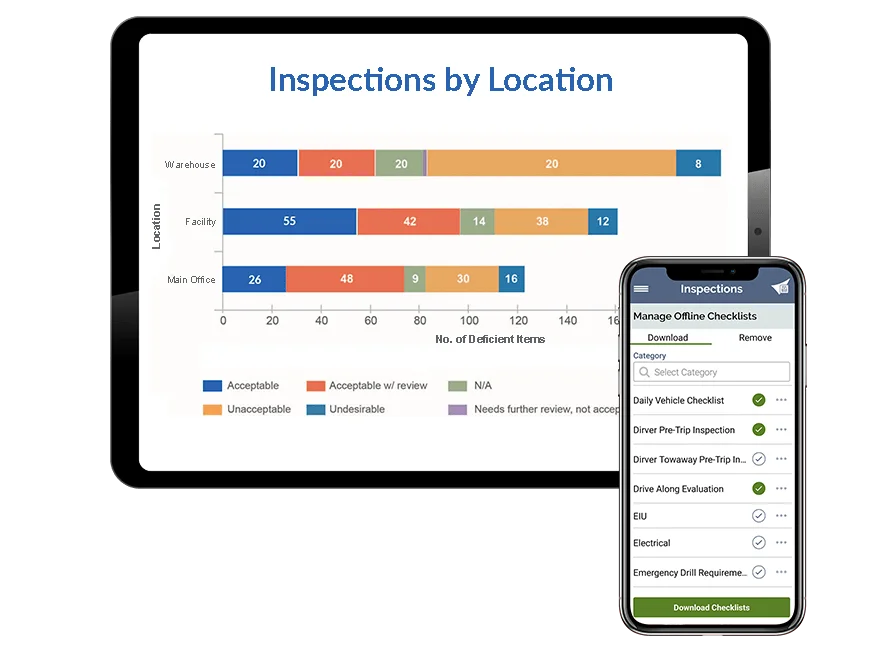

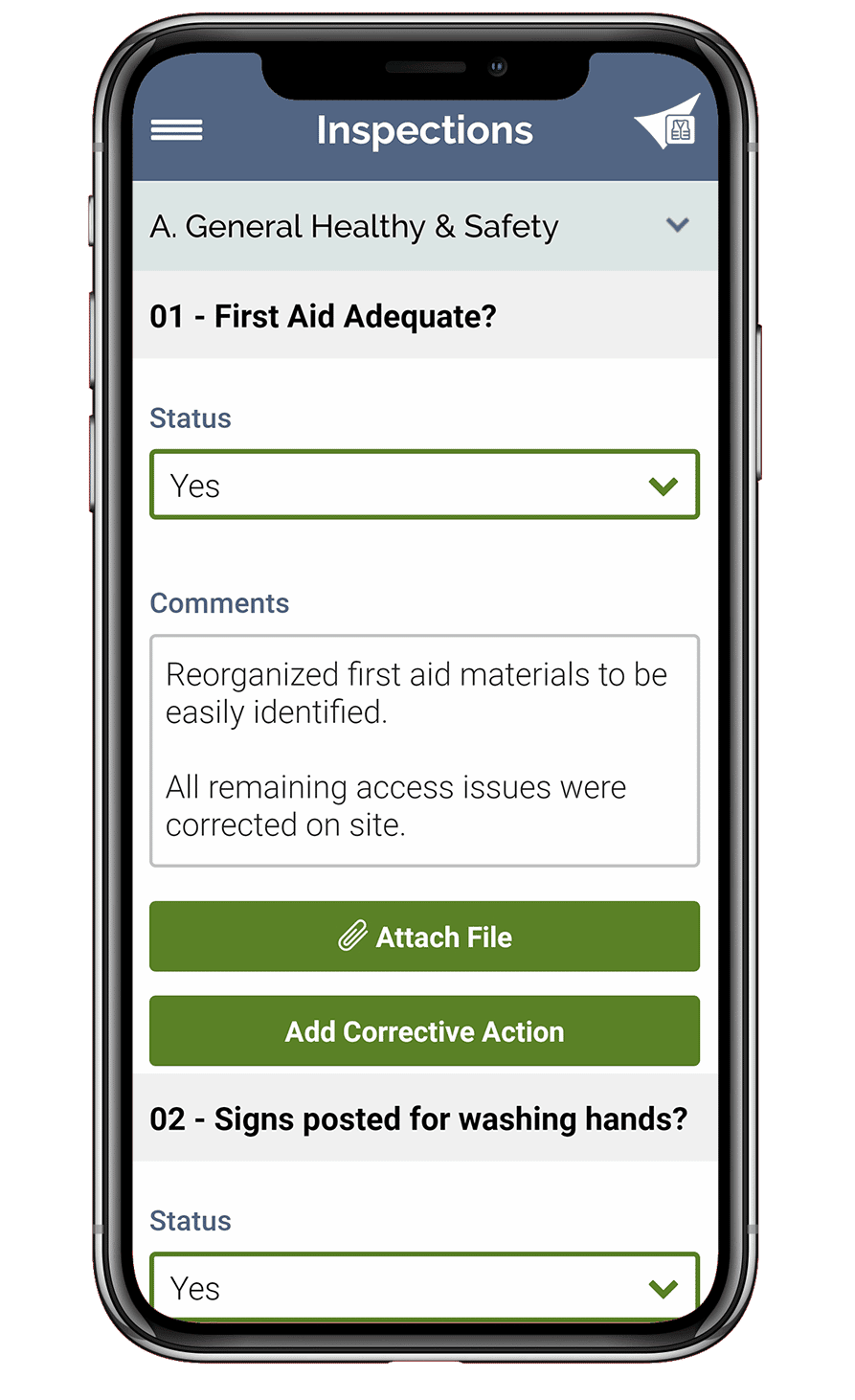

You may also want to consider downloading Vector EHS Management’s mobile inspections app. The app enables you to upload pictures, use a pre-built forklift inspection checklist and can even be used with or without internet access. If you have an iPhone or Android phone, downloading this app can help your workforce to streamline and improve your forklift inspections. Sign up for a free trial of the Vector EHS Management mobile app today.