February 13, 2018 9 min read

How to Meet OSHA Crane Inspection Requirements

Industry:

Solution:

The Occupational Health and Safety Administration (OSHA) 1910.179 standard requires organizations to regularly inspect overhead cranes to prevent potential accidents. As such, you need to know what parts of the crane to inspect, how often to inspect them, and the tools available to assist in conducting inspections.

Complying with OSHA’s standards is not only required to avoid expensive fines, but to improve safety. OSHA has published these standards and regulations to minimize the numerous safety hazards in the manufacturing industry.

In this article we’ll go over some of the basic requirements of OSHA’s 1910.179 crane inspection standard and what you can do for easy compliance.

Have an OSHA 1910.179 Crane Inspection Checklist

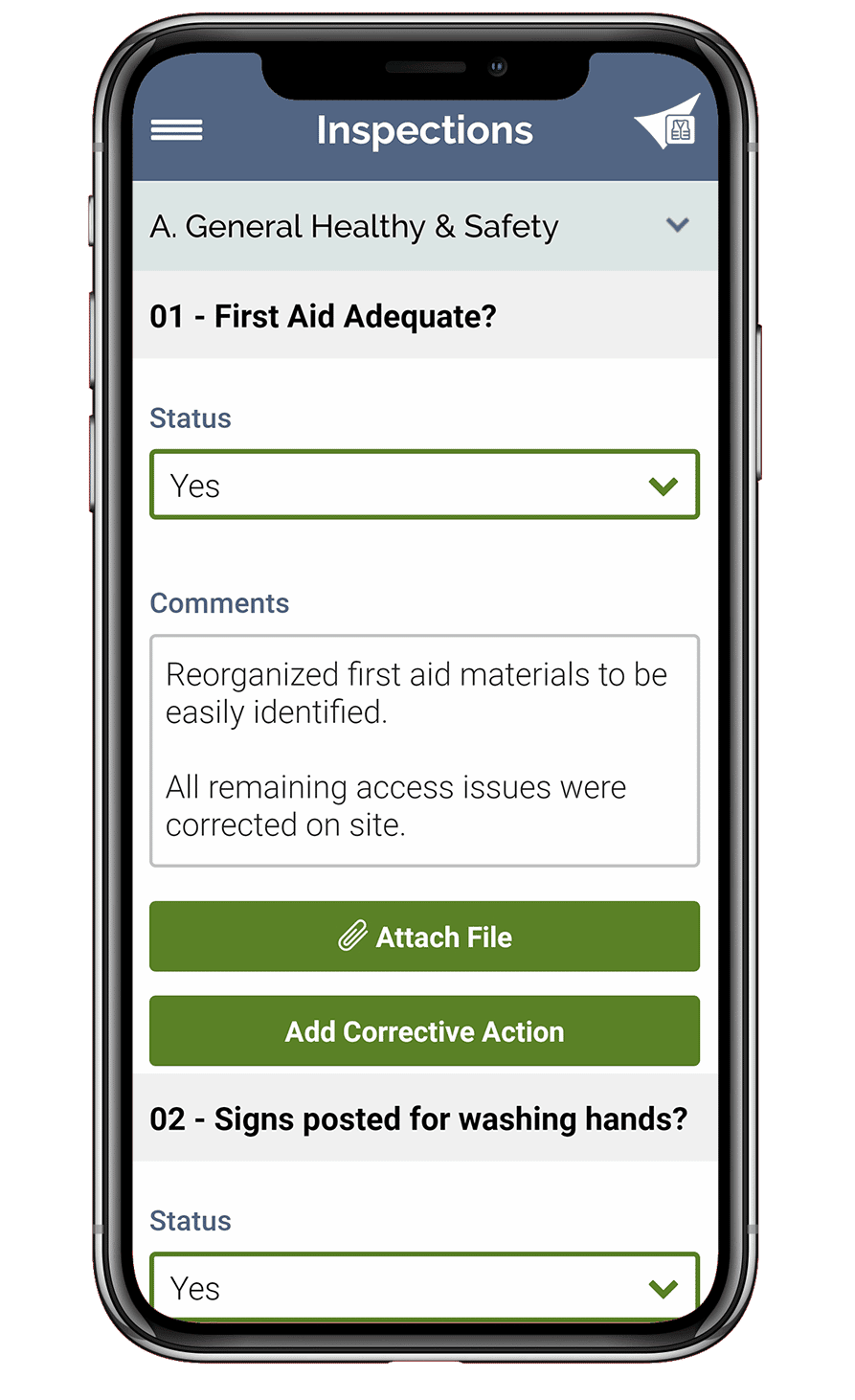

OSHA’s Standard 1910.179 outlines the requirements for overhead and gantry cranes in order to prevent workplace injuries. While the standard is filled with legal wording, you can use its different sections to create inspection checklists for easy compliance.

For example, section 1910.179(e)(6) talks about machine guards for moving parts. Under this section, OSHA requires that “guards shall be securely fastened”. Therefore it only makes sense you should use an inspection checklist that asks “Are guards securely fastened” to ensure safety and compliance with OSHA’s regulations.

Keep in mind you’ll want to create different checklists based on different parts of the standard. You can save the more detailed sections of the standard for less frequent, but more thorough, inspections (more on that in a bit). Combing through the standard for relevant sections may seem time consuming but it is a guaranteed way to comply with OSHA’s laws.

Of course, you can always save yourself time by using software for inspections that comes with pre-built checklists based off of these regulations.

Vector EHS Management Software empowers organizations – from global leaders to local businesses – to improve workplace safety and comply with environmental, health, and safety regulations.

Learn more about how our software can save you valuable time and effort in recording, tracking, and analyzing your EHS activities.

Learn more about how we can help:

- Incident Management Software →

- EHS Inspection Software →

- Key Safety Metrics Dashboard →

- Learning Management System (LMS) and Online Training Courses →

- Mobile Risk Communication Platform

Download our EHS Management Software Buyer’s Guide.

How often to conduct crane safety inspections

OSHA requires that all active cranes must be inspected once a year at the minimum. However, depending on the cranes usage, additional inspections will be required.

Crane inspections fall under two general categories based on the intervals between inspections. Inspections that should be conducted daily or monthly are classified as frequent inspections. All other inspections are considered periodic inspections, which can occur bimonthly, quarterly, or yearly.

You can download free overhead crane inspection checklists for frequent and periodic inspections here:

Crane Inspections, Simplified

Download

Frequent Inspections

Frequent inspections cover the operating mechanisms, parts of the air or hydraulic systems, and the hooks and hoist chains. These items need to be visually examined on a daily basis. OSHA also recommends testing and examining these items before each shift.

The hooks and hoist equipment of cranes also need monthly inspections by a certified crane inspector. Written records of these inspections that are signed and dated by the inspector must be kept on file.

Of course, it’s smart to keep records of all frequent inspections in the event a incident occurs. Doing so will help protect you if OSHA investigates your safety procedures to determine liability.

Periodic Inspections

Periodic inspections look for loose bolts, cracked sheaves, damaged locking devices, and wear on the braking system. These inspections also examine the load and wind indicators, gasoline and electric power-plants, electrical wiring. Cranes that are used for “normal” or “heavy” service should have their periodic inspections conducted yearly. Only cranes in “severe service” are required to be inspected quarterly.

A crane that hasn’t been used for more than a month but less than six months requires all frequent inspections before being used. Cranes that are idle for more than six months will require a complete inspection of both frequent and periodic inspections.

Use Inspection Software and Mobile Apps

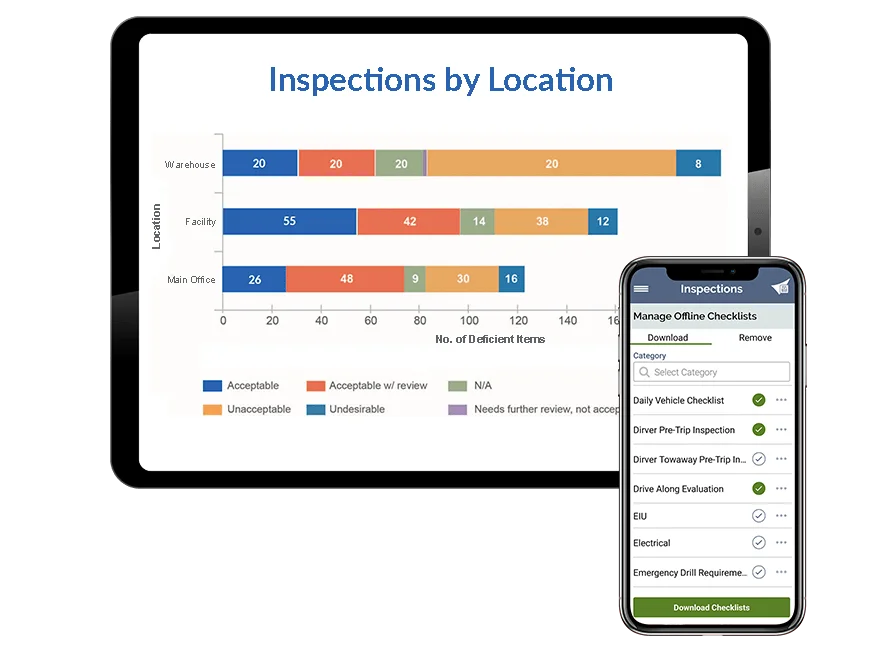

You may also want to consider using crane inspection software or a crane inspection app to help you comply with all these OSHA regulations. Technology eases the burden of tracking any deficient items found, as well as making sure inspections are being conducted as required.

Using a crane inspection mobile app will streamline the inspection process and encourage workers to take inspections seriously. Mobile apps offer numerous benefits that can help with safety inspections.

At the bare minimum, we recommend using a mobile app that allows workers to upload photos taken during the check to see exactly what needs to be fixed.

The best inspection mobile apps and software can also work without internet access, and come with pre-built checklists based on OSHA’s regulations. Most importantly, it will keep accurate records and the date of inspection to prove OSHA compliance.

If you want to learn more about inspection software and inspection apps, sign up for a free trial of Vector EHS Management. Signing up for a demo will give you a better idea of exactly how these tools can help you meet OSHA’s crane inspection requirements, as well as other health and safety regulations. You can also download the Vector EHS Inspections app, to see exactly how easy it can be to conduct crane inspections.