November 12, 2023 28 min read

How to Create Effective Manufacturing Training Programs in 6 Steps

Industry:

Solution:

Want to know how to design, create, and deliver effective manufacturing training programs at work? The kind of manufacturing training that truly helps workers acquire new knowledge and develop new skills they can perform on the job? The kind that will have a real, measurable effect on key business KPIs such as average time to onboard a new employee and even production, revenue, and profit?

We’ve got a pretty simple, six-step formula for success for you to follow in this article. Just put these six steps into action at your manufacturing facility and you’ll have more skilled workers before you know it. The employees will thank you for it (after all, they want to know how to perform their jobs well) and so will your bosses.

What is a Manufacturing Training Program?

A manufacturing training program is a structured educational program designed to equip employees with the skills and knowledge necessary to be productive and safe in their manufacturing role. This program encompasses a range of topics, including safety protocols, equipment operation, quality control, and industry-specific processes. Through a combination of eLearning and hands-on experiences, participants gain the competencies required to excel in various manufacturing roles, fostering a workforce that contributes to operational efficiency and product quality.

The Six Steps Behind an Effective Manufacturing Training Program

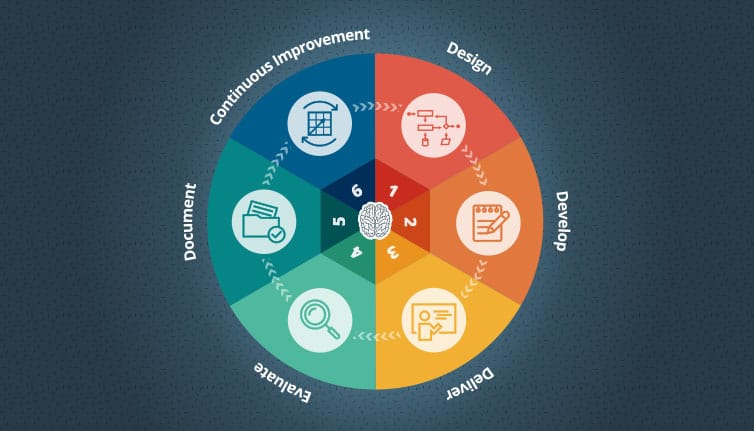

There are six basic steps to pulling together a manufacturing training program at your work:

- Step 1: Designing Manufacturing Training Programs

- Step 2: Developing Manufacturing Training Programs

- Step 3: Delivering Manufacturing Training

- Step 4: Evaluating Manufacturing Training Programs

- Step 5: Documenting Manufacturing Training

- Step 6: Continuous Improvement of Manufacturing Training Programs

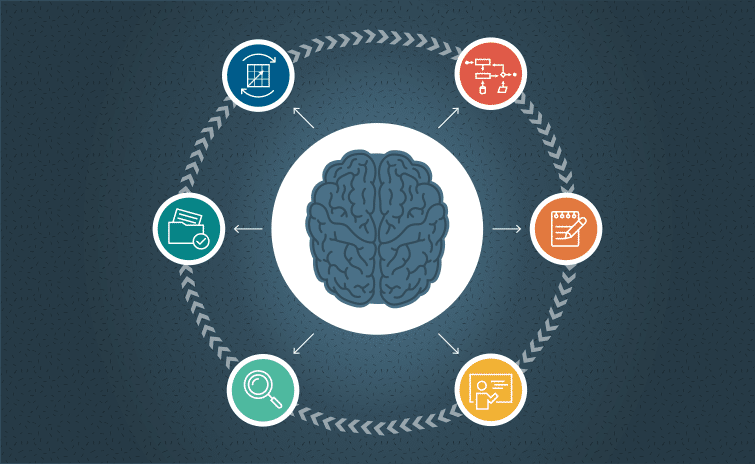

For starters, check out the image below. It illustrates a process starting at 12:00 on the clock and moving in a clockwise fashion.

What We Want to Tell You About Manufacturing Training Programs:

First: The image above represents a never-ending cycle. And that’s true of manufacturing training programs, too. You’ll never really be “done.”

Second: The phase at the end of the cycle, before you go back to design, is Continuous Improvement. You’ll never be done with a manufacturing training program because you always can (and should) keep trying to make the program better and more effective. Think of it as job security!

Step 1: Designing Manufacturing Training Programs

Rather than just jumping in and starting to create training, it’s important to work through the initial design phase. In short, that means planning your training.

The design process includes several steps, including:

- Performing a training needs analysis

- Identifying and measuring the business goals or metrics your training is intended to influence

- Completing a task analysis

- Creating the learning objectives

- Performing a learner analysis

- Additional things to consider

Let’s look in more detail at each.

Training Needs Analysis

There are two points of a training needs analysis.

The first is to determine the “problem” you’re trying to solve. Do employees not know how to perform a specific job task, for example?

And the second is to determine if training is the right solution. Sometimes you’ll find that training is appropriate, but in other cases you’ll find that other solutions would be more appropriate (read more about this here).

Identify the Business Goals and/or Metrics You Want the Training Program to Influence

At some point, after the training is complete, you’re going to want to know if the training worked. And by that, we mean you’re going to want to know if it had a positive, measurable effect on one or more business goal. Because remember, companies don’t train workers without a reason. There’s always a business goal behind it.

But if you wait until the training is complete before you think about this, you’ll be behind the proverbial eight-ball. You won’t be able to measure and demonstrate the effectiveness of the training program.

Now’s the time to:

- Determine the business goal the training is intended to improve.

- Determine what key performance indicator (KPI)/ business metric is used to track that business goal.

- Record that business metric now and set up a schedule for continually monitoring and documenting that metric.

Once the training has been complete, you can compare the previous metrics with the current metrics and look for a trend. Hopefully, a positive trend.

Remember that simply saying the training is complete, or that workers passed a test, or that workers spent a certain amount of time in training, is never enough to justify the value of the training.

Task Analysis

In some cases, your training may be focused on creating awareness or teaching knowledge to employees. Maybe it’s a new company policy.

In other cases, though, the training will be intended to help workers develop new skills so they can complete a specific task or procedure on the job.

In those cases, you’ll want to break the procedure down into a series of smaller steps. This will help you prepare to teach the steps of that procedure to workers.

This process is known as the task analysis.

Learning Objectives

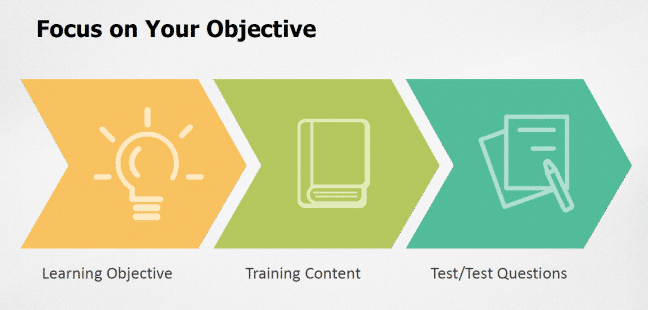

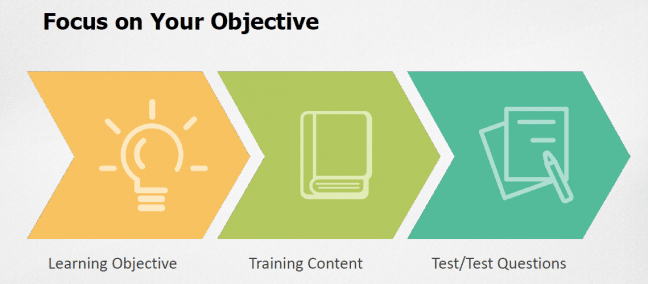

The next step of designing manufacturing training is to create the learning objective(s).

A learning objective is something you want the employees to be able to do when the training is over. It’s the entire reason for holding the training. It’s what you want to help workers learn to do so that they can do it on the job and the business can therefore meet its business goals.

Once you’ve created your learning objectives, they should function as a road map for all the rest of your training. You should create training content to help workers satisfy those learning objectives. You should notify workers that the training is intended to help them perform those learning objectives. You should create assessments to determine if workers can perform those learning objectives after training. And you should observe on-the-job behaviors after training to see if workers are performing those behaviors, skills, and/or procedures on the job.

Learner Analysis

Your training should always be learner-centric. What does that mean?

It means you put the employees and their learning needs at the top of your list and you create training to match their learning needs.

As a result, you’ll need to learn as much about the learners–the employees you’ll be training–before you create the training.

There are many ways to do this. Maybe the best is to talk to them and ask them questions.

In addition, though, you might try having them complete surveys and questionnaires, observing them while they’re on the job, or getting information about them from their supervisor or HR.

Here are some characteristics to try to learn about:

- Their current ability to perform the task and satisfy your learning objective

- Their work schedule and availability for training

- The language they speak, understand, and communicate in (both written and verbal communication)

- Their reading level and capabilities

- Their ages

- Cultural group and/or ethnicity

- Gender

- Any physical handicaps

- Learning preferences (one-on-one training; instructor-led classroom style training; group collaboration; written; self-guided online learning; etc.).

Delivery Method of Manufacturing Training

You can deliver training in different methods. What’s a training delivery method, you ask?

Training delivery methods you can use for your manufacturing training include:

- Written training materials

- Video-based training materials

- Webinars

- One-on-one training

- Instructor-led training with a group in a class

- Mentoring, shadowing, and/or following programs on the job (OJT)

- Online training materials

- And more

Mountains of research data shows that, in general, there’s no one training delivery method (or media) that’s more effective than the others. The research shows that all of them can be equally effective. What really matters is in the instructional method (for example, the instructional method of “providing helpful feedback” can be used in classroom-style training, in field-based training, during a live webinar, and even in an online eLearning course).

You’ll often find that one type of training delivery method (instructor-led classroom training, for example) may be more appropriate for a particular training need, while a different training delivery method (online training, for example) may be more appropriate for a second training need. And in still other cases, you’ll find it’s best to deliver training in more than just method (such as introducing a topic with an online training course and then following up with an instructor-led classroom session).

Because of this, it’s best to use what training experts call a blended learning solution for manufacturing training. In short, this means picking the best training delivery method, or the best combination of training delivery methods, for each training need.

Note: In addition to the blended learning article linked above, you may want to download our free Beginner’s Guide to Blended Learning.

Partnering with Training Providers

At some point, you’ll want to think of how much training you want to create yourself and how much you want to create with professional manufacturing training providers, either buying off-the-shelf manufacturing training materials or getting custom manufacturing training created for your company.

Beginner’s Guide to Online Training

As manufacturers look to close skills gaps and improve employee retention, there is no better time to look at the use and benefits of online training

Download Now

Step 2: Developing Manufacturing Training Programs

Once you complete the design step, it’s time to roll up your sleeves and develop your training program.

Using Credible Sources of Information

Make sure the information you’re including in your content is from credible sources.

You’re probably already aware of this, but you shouldn’t include stuff in your training just because you heard it “somewhere” or because you read it on the Internet.

Instead, make sure you’re getting your information from credible sources:

- For operations and job-task training, consult manufacturers, in-house subject matter experts and/or engineers, supervisors, managers, and employees.

- For manufacturing safety training, check regulatory agencies such OSHA, organizations such as such as the Chemical Safety Board (CSB), and professional safety organizations such the ASSE and NSC.

- For HR and/or other compliance-based training, check regulatory agencies.

You may also want to consider partnering with training providers to get experienced knowledge for your manufacturing training, manufacturing safety training, and other workforce training needs.

Make Your Training Human-Centered and Learner-Centered

As a training designer, it’s notoriously easy to get overly focused on your content or your training technology and forget about the people who are supposed to learn from the training and who will need to change or improve their job performance once the training is over. But all that focus on training content and perhaps training content can lead to training that’s less effective, not more.

After all, the training is supposed to help employees learn. Why shouldn’t your training design, development, and delivery focus primarily on the needs of the learners?

There are many ways to do this, and a good solid learner analysis is a great way to start.

You might also want to consider some alternate methods of learning more about the learners–this introduction to design thinking might be a fruitful path for you.

Keep Your Training Short

The human brain acts as a limit to the amount of information we can process and store at any one time. It’s only a small amount of information–about four “bits” at any one time.

And we can only keep that information in our working memory (you might think of this as short-term memory) for a very short period of time. About 15 minutes, tops.

As a result, training that goes on for an extended period of time is your enemy and works against you. Keep it short and sweet and return for more later if necessary (this is related to the next section about chunking).

Chunk Your Manufacturing Training

To “chunk” means to break up training materials into shorter, organized parts and put them in a logical order.

Chunking helps people learn because it’s a good way to avoid overloading them with too much information at one time.

This article about chunking training explains why and how to chunk in much greater detail.

Language: Speaking, Reading, Understanding

When you performed the worker analysis, one thing you investigated was the language relevant to the employees who will complete training.

It may turn out that you have a multi-language workforce. If so, you may want to provide your manufacturing training in multiple languages as well, as we’ve demonstrated below.

In addition to speaking in the correct language(s), it’s also important to speak in a casual, conversational tone that’s appropriate for the workers who will be receiving the training.

Try to avoid:

- Overly formal language

- Academic language

- Long, complex sentences

- Big words

- Jargon

- Acronyms

- Abbreviations

For more about this, check out our article with tips on how to write training materials and our discussion of this book with tips on using language so that training “sticks.”

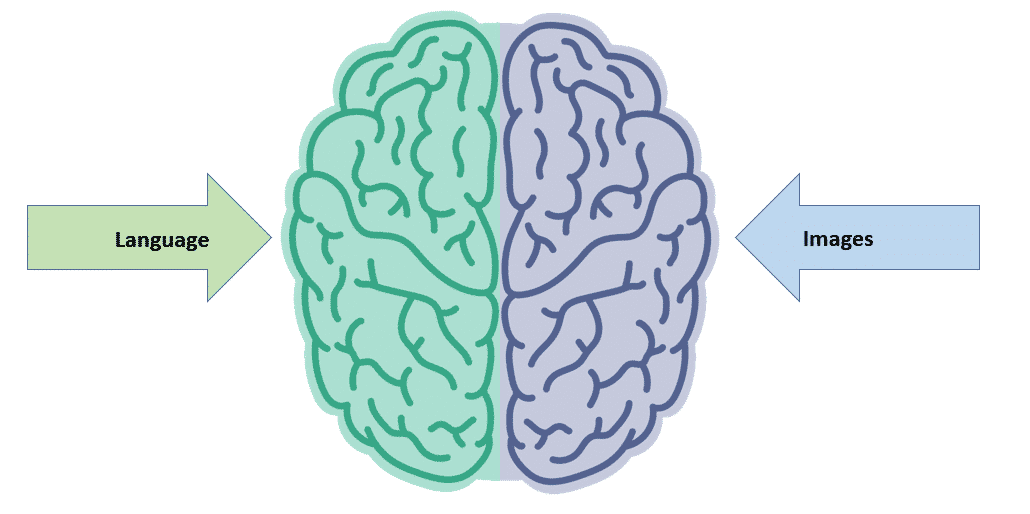

Your Manufacturing Training Should Include Visuals

You can think of the brain as having two separate but complementary “processing channels” for learning information. One is for language, and the other is for visual images.

If your training materials provide well-designed visuals in sync with spoken language, your employees will learn much more effectively. It’s like the old saying about how “the sum is greater than the whole of the parts.” A training multiplier comes into effect.

Be sure your training includes both audio and visuals so you can take advantage of this training maximizer. This doesn’t mean you have to do something super complex. It can be as simple as drawing on a white board or flip chart, or using the SmartArt inside Microsoft Office software programs. Some ideas are below.

Although you don’t need fancy graphic tools and skills to make useful images, this is nonetheless one of the strengths of online manufacturing training courses, as the images below from some of our manufacturing health and safety training courses demonstrate.

For another example, check this sample from an online course about Process and Instrumentation Diagrams (P&IDs).

Awaken Prior Knowledge Related to the Training Topic At Beginning of Training Session

As learning experts and cognitive psychology have explained to us, when people are exposed to new information, they try to relate it to prior knowledge (these “packets” of knowledge in our memories are known as schemas). Once they’ve integrated the new information with the prior knowledge, they then “store” it all together in a newly modified packet of information (or schema).

You can greatly aid this process, and create a more effective learning experience, if you do something to trigger the employees to open up, access, or begin thinking about that prior knowledge at the beginning of training. This will help with the process of integrating the prior and new information, and it will help with long-term storage of the new information.

Use Metaphors, Similes, Analogies, and Other Forms of Comparison and Contrast

It’s easier to make sense of new information if it’s presented in relation to stuff we already know and understand (this is related to the point above about awakening prior knowledge).

Using what’s called “figurative language,” including metaphors, similes, and analogies, makes this easier. And so it will make your training more effective.

Read more about the use of metaphors, similes, and analogies in manufacturing training.

Tell Stories

People are basically hard-wired to appreciate, listen to, and anticipate the twists, turns, and ending of a story.

And as a result, it’s a great idea to present your manufacturing training in the form of a story when you can.

Want more tips on this? Check out this on story-based learning and why you should use it.

Have Employees Practice/Make Decisions and See Consequences

People are active learners. That means we learn by doing.

As a result, you should create training that includes built-in chances for employees to practice new skills, see the consequences of their performances, and receive supportive, helpful feedback. All in an environment that’s safe and protects them and others from any negative results that would result from making a mistake in a real work environment.

Hands-on training is a great way to do this. Scenario-based online training as described in this video can help, too.

Read more about scenario-based eLearning courses here.

Use Spaced Practice

Here’s a truth you probably already know about training: people forget stuff. They forget a lot of stuff and they forget it quickly.

If employees at your company do this, it’s not because they’re bad learners. And it doesn’t necessarily mean they weren’t paying attention during training. It’s just that they’re human–which is probably a good thing, right?

That’s why training shouldn’t be a one-and-one, once a year thing. And that brings us to the importance of refresher training and something called spaced practice (which basically means giving employees repeated chances over time to practice new skills).

Those refresher training sessions don’t have to be super-long. A quick eLearning course may be quite effective as a refresher. You may also want to look into microlearning for refresher training.

Have Employees Think About Their Own Learning

Hang in there with me here, because this gets just a tiny bit abstract.

People learn better when they think about what they’re learning and how well they are learning it (or how well they understand it).

This process of thinking about what you’re learning and how well you’re learning is part of what is known as metacognition. There’s a lot to say about this topic, but just knowing that your employees are more likely to understand and remember manufacturing training if they self-monitor their own learning during training will help.

To help employees with this, you can build-in moments into the training where you invite workers to ask themselves how well they understand what’s being discussed. You may even provide pen and paper so they can write notes to themselves. This can be a useful way to make sure you’ve had a chance to address any confusions and uncertainties as well.

Low-stakes or no-stakes testing during training is also a good way to stimulate metacognition and enhance learning.

In General, Use Evidence-Based Training Practices and Avoid “Learning Myths”

We’ve listed several evidence-based training practices above, but there are more. We recommend you research them and use them.

Likewise, there are many “learning myths” out there-things that people think help to create effective training even if there’s no evidence to suggest it’s true or if there’s evidence disproving it.

Step 3: Delivering Manufacturing Training

Let’s consider some aspects of delivering the training now.

General Considerations for Delivering Training

As with all training, it’s important to remember that manufacturing training should be matched to the learning needs of the employees. Keep this in mind whenever any kind of training is being delivered.

Face-to-Face Trainers and Effective Training Delivery

If you’re leading face-to-face training, either in a classroom our out in the field, it’s important to keep the employee’s learning needs in mind (and central).

Remember to create an active, engaging experience for the learners. For one thing, that means you want to avoid long, one-sided monologues or lectures. Don’t let your training become one these common and cliched training worst-case situations:

- The sage on the stage

- Spray-and-pray training

- Information dumps

Make sure employees play an active role. Ask them questions. See if there are opportunities for them to lead discussions. Have them break up into groups to discuss things on their own. Have hands-on exercises or written exercises for them.

Online and Virtual Manufacturing Training Delivery

As is true with face-to-face training, it’s important for online and virtual training to be engaging and interactive as well.

Look for practice tests, interactivity, compelling visuals, short and crisp audio narration, and scored assessment tests.

Spaced Practice

It’s basically human nature to forget training almost instantly. In learning & development circles, this is known as the forgetting curve.

And as a result, it’s a trainer’s job to fight against that natural tendency that we all have to forget. Training must be specifically designed to combat the forgetting curve.

Fortunately, there’s a great deal of research showing that spaced practice is a great and proven way to help combat or even reverse the forgetting curve.

But what’s spaced practice? It’s pretty much what it sounds like. Introducing the employee to the training material, and allowing them to practice their mastery, at different points spaced throughout time. If you’re familiar with the idea of refresher training, you know the basic concept.

Some tips for spaced practice include:

- Provide pre-training before the primary training

- Introduce a training concept at several different times during the primary training

- Re-introduce a training concept at several times after the primary training (not immediately after, but before a year has passed)

Microlearning

An exciting new trend in the learning and development work is the movement toward microlearning.

Generally, this means training in short bursts-as little as 1, 3, or 5 minutes.

Research has shown it’s very effective. In addition, it’s great for training delivered to and completed on mobile devices, and it’s a great tool for spaced practice.

Performance Support

It’s great to train people, but sometimes it’s even better to just get the information that they need to perform their jobs into their hands where and when they need it: on the job, on the floor, in the field, etc.

That’s what performance support is all about.

Click to read more about performance support and job aids.

70/20/10

The idea behind 70/20/10, which is also sometimes known as Experience, Exposure, and Education (or the 3 E’s), is that workers learn only a small amount of their job knowledge and skills from formal training.

The idea is (and the numbers below are just rough estimates-don’t get caught up on them), that workers learn:

- 70% of what they know from direct on-the-job experience (the Experience)

- 20% of what they know from their coworkers (the Exposure)

- 10% of what they know from their formal job training (the Education)

So in addition to trying to do everything you can to deliver the best training possible, don’t forget you may be able to impact the organization even more by working to facilitate learning that occurs directly on the job and learning that occurs when coworkers share information.

Read more about 70/20/10 here.

Step 4: Evaluating Manufacturing Training Programs

You can’t just deliver training and walk away. You should evaluate it to see if it was effective. And if it wasn’t, you should revise it to make it better.

This starts when you’re delivering training (if you’re the instructor in the field or in the class). Are people confused? Are they glassy-eyed? Are they bored? That’s one level of evaluation, and something you should be observing real-time.

But on top of that, there’s a well-known, four-level method for evaluating the effectiveness of training.

For those of you in the know, you’ll recognize the four-level evaluation method below as being based on the Kirkpatrick Training Evaluation model.

Level 1: Employee Reactions to Training (“Smile Sheets” or Surveys)

You may be familiar with the idea of handing out surveys so that employees can tell you how good a training session was. These surveys are often referred to as “smile sheets.”

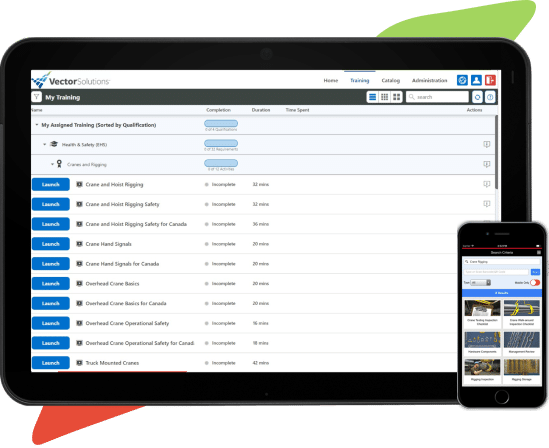

They can be done with pen and paper, with online survey tools such as SurveyMonkey, or even with surveys created inside your learning management system (LMS).

These evaluations don’t provide perfect information, but in general, they’re a good idea. It’s a piece of the puzzle.

However, they are traditionally written in a poor manner that makes the information we receive from employees less helpful than it could be.

Here are a few tips for writing them more effectively.

- Include open-ended questions and let employees write or type responses when possible (you’ll often get the most useful information this way)

- Don’t ask if employees “liked” the training or the trainer. Studies show there’s almost no connection between “liking” the training or trainer and the amount of true learning that occurred.

- Do write questions that ask if the training prepared the worker well to perform the job at work (and/or satisfy the learning objective).

- Don’t use numerical answer choices (1, 2, 3, 4, 5) and/or choices based on agreeing and disagreeing with a statement (strongly disagree, somewhat disagree, neither agree nor disagree, somewhat agree, strongly agree)

- Do answer options that include specific phrasing about whether or not the training prepared the worker to safely perform a job task

- Do include questions and answer options that, when reviewed by a trainer after the data is collected, will provide solid, concrete information about whether or not the training was effective and, if it wasn’t effective, how it can be improved

Click the link to read our more detailed article about how to write better level-1 evaluations/smile sheets.

Level 2: Tests and Other Assessments of Employee Learning After Training

The next level is to have an assessment, or test, to determine if the employee can satisfy the learning objectives when the training is over.

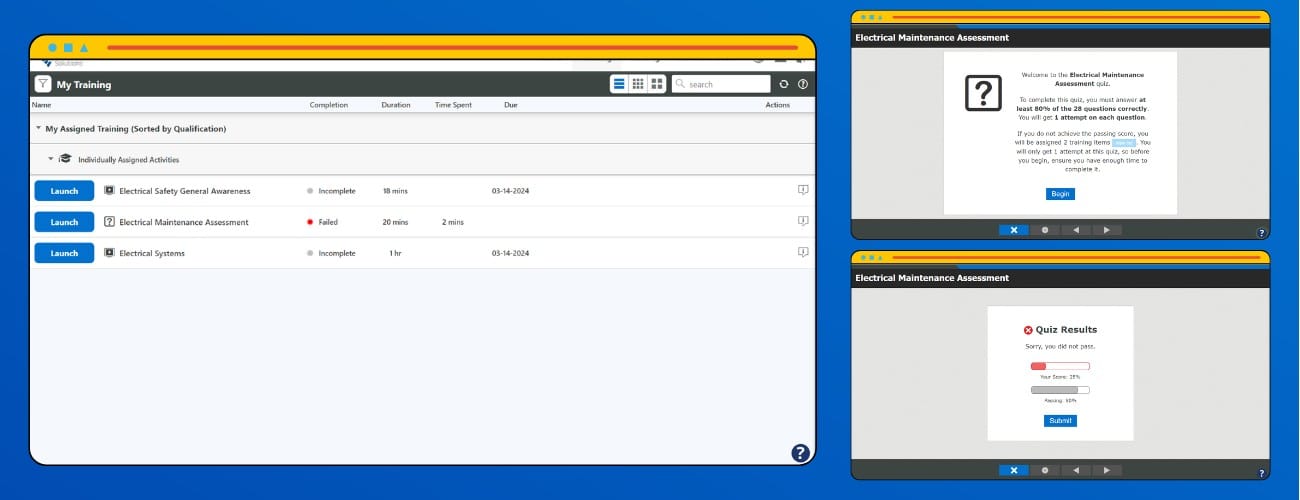

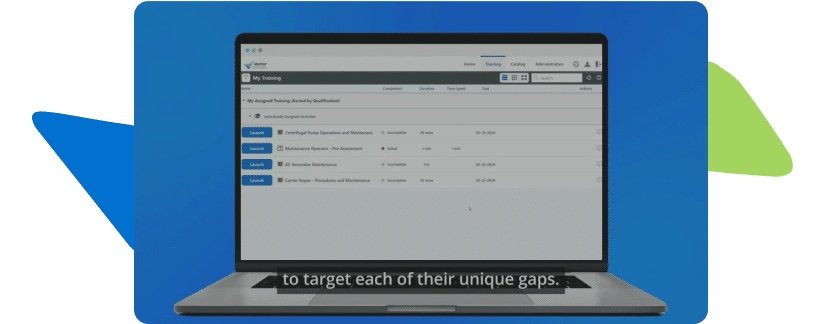

In some cases, a “knowledge” test of facts and ideas will be what’s called for. These tests can be performed orally, on paper, or electronically using a learning management system (LMS). Many LMSs will even include tools to create your own custom online quizzes, as illustrated below with Vector Solutions’ Competency Assessment Tool.

There are numerous ways to use an employee competency assessment. This tool can conduct pre-assessments for job applicants, improve onboarding, identify skills gaps, and more. Using this solution in our LMS allows you to:

- Save time by identifying skills and knowledge gaps faster

- Customize training plans to be more meaningful and relevant

- Elevate reporting

- Streamline training and reporting workflows

- Improve learning outcomes

Vector Solutions’ Competency Assessment Tool

Efficiently create, manage, and assign Competency Assessments to your workforce. Then automate assigning required training based on each employee’s results.

Watch How it Works

In other cases, especially if the learning objective is skill-based, you’ll want to see the employee perform the procedure or job task correctly. There are mobile training apps and devices that can help with this.

A few additional notes about testing before we go:

- All tests should be designed in order to assess the employee’s ability to satisfy the learning objectives.

- Testing is actually a helpful aid to the learning process. This is known as the testing effect, and it has many benefits, including contributing to metacognition. There are lots of places to read up on the testing effect, but the book Make it Stick is a good place to start.

- Remember that because of the already-mentioned forgetting curve, employees may do very well on a test immediately after training and then forget nearly everything in as little as a day (and certainly a week or month) unless you do something to reinforce the learning. A test that’s delayed a day or week as part of a spaced practice training may give you more accurate results of true learning and may also combat the forgetting curve.

We’ve written a number of articles about workforce testing. They’re linked below for you.

- Testing Best Practices

- Valid and Reliable Tests

- Testing and Fidelity

- Writing Multiple Choice Questions

- Writing True/False, Matching, Drag and Drop, and Other Question Types

Also, we recently discovered, enjoyed, and learning from this podcast about testing with Connie Malamed and Michael Rodriguez.

Level 3: Observations of On-the-Job Safe Work Practices

Tests are part of the puzzle, but it doesn’t end after the test. Especially given people’s tendency to forget training quickly.

Once the training is over, you’ll want to observe workers on the job to make sure they’re performing the new skills correctly.

If they are, great. Give them recognition and support for doing so.

If they’re not, remind workers or help them relearn the skill(s). Also, try to find out why. Maybe it’s because there was a problem with the training, and they either never learned or they have forgotten. But maybe there’s something else going on-maybe a manager is telling them to ignore the training, or maybe a work process makes it difficult or impossible to implement the training.

Of course, if it IS clear there’s a training problem, you’ll want to remedy that. That may be as simple as a simple verbal reminder or some refresher training. Or maybe you’ll have to go back and modify the original training.

Level 4: Effect on Key Workplace Metrics (and Other Business KPIs)

Near the top of this article, we mentioned the importance of:

- Knowing the business goals or metrics (KPIs) that training is intended to affect

- Learning how those business goals are tracked

- Getting a baseline, pre-training measurement of those goals

Now that training is over, you’re going to want to measure those goals again, and create a system for measuring them over time to prove that the training was effective (or determine it wasn’t).

This article demonstrates using KPIs to measuring training effectiveness.

More Thoughts on Evaluating Training Effectiveness

In this section, we introduced you to the well-known and commonly used Kirkpatrick four-level training evaluation method.

However, it’s worth knowing a few things:

- The Kirkpatrick model isn’t the only training evaluation model out there

- The Kirkpatrick model has its critics

- You may find other training evaluation models equally or more helpful

- You may find that different situations call for using different training evaluation models

To help you consider all this, please check out the two following recorded webinars/discussions:

Step 5: Documenting Manufacturing Training

Industrial Learning Management System (LMS) Brochure

Learn how you can easily schedule, deliver, and track training to improve workforce performance and efficiency

View Brochure

Step 6: Continuous Improvement of Manufacturing Training Programs

Creating effective manufacturing training programs is a process that never really ends.

Because once you’ve got through the five steps above, you should take that evaluation information and use it to improve your program. Plus, there will always be new things that occur at work and changes to account for too.

So manufacturing training, like so much of manufacturing, becomes part of a continuous improvement cycle.

For more on continuous improvement, download our free PDCA Cycle infographic and check out our article on Continuous Improvement at Work.

All Steps: Managing Effective Manufacturing Training Programs

Effective manufacturing training programs don’t spring up from the ground on their own.

Instead, they require dedicated effort from many people and the allocation of resources and time.

And that requires an element of management.

Let’s look at some important considerations for managing a manufacturing training program.

Managing & Administering Resources

Resources, including time, money, supplies, and people, must be allocated to the training program. Goals must be communicated and understood. Roadblocks and obstacles have to be cleared.

Roles Defined

People have to have specific roles and they must know what those roles are.

Ensuring Training Tasks are Completed

Someone has to ensure that the different stages, processes, and tasks related to manufacturing training programs are completed and on schedule.

Transform Your Training Program for Success

By following the six steps, manufacturers can create comprehensive and impactful training programs while ensuring operational efficiency, safety, and compliance. These programs not only equip employees with the necessary skills and knowledge but also contribute to a culture of continuous learning and development within the organization. With the rapid advancements in technology and evolving industry standards, it is imperative for manufacturers to prioritize training initiatives to stay competitive and adapt to changing demands.

By investing in your workforce through robust training programs, manufacturers can foster a skilled workforce, enhance productivity, and ultimately drive business success in the dynamic landscape of the manufacturing industry. Request a demo today to learn how our LMS and online courses can help you achieve your training goals.