Supplemental and Recycled Fiber – Fiber Prep and Screening

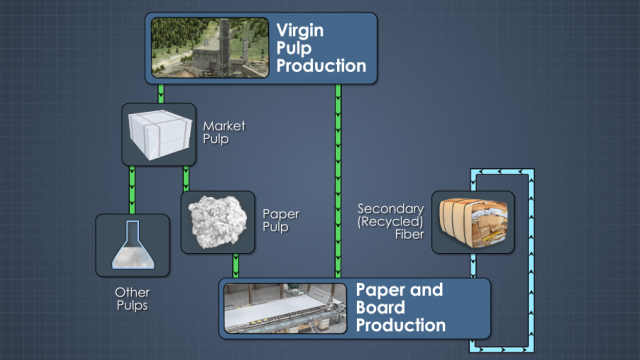

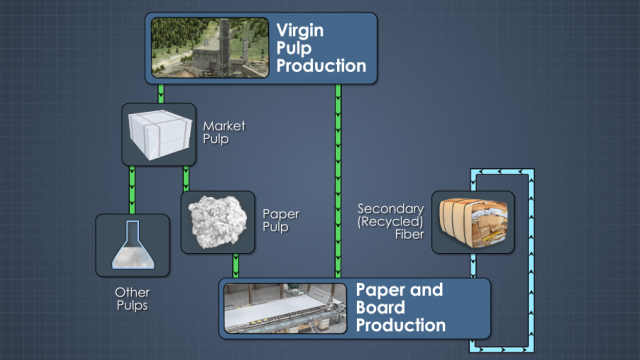

Wood fiber accounts for more than 90% of the raw material used in the production of paper and board products, and it can come from a variety of sources. These sources can be slushed virgin fiber that is produced onsite, market pulp from other pulp mills, or recycled/secondary fiber. This course will cover the preparation and screening of market pulp and recycled fiber at papermaking facilities.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Define the terms: “market pulp,” “recycled fiber,” “pre-consumer waste,” and “post consumer waste”

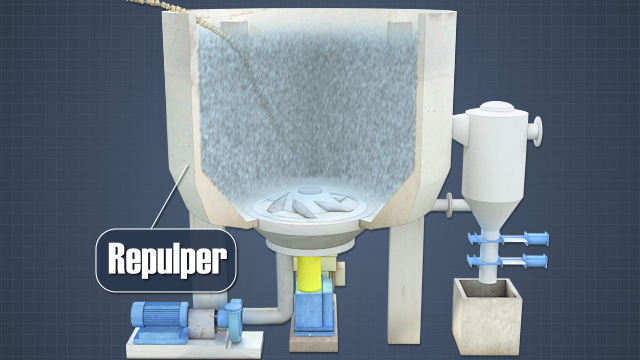

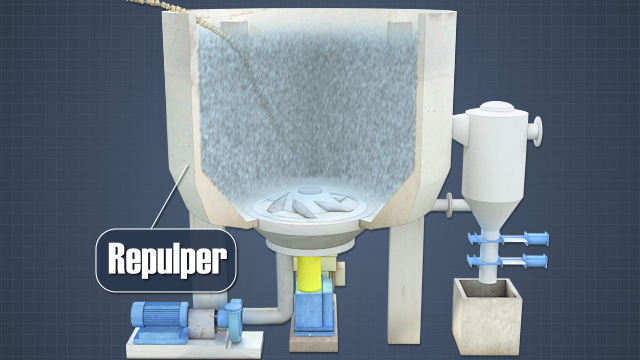

• Identify and describe the primary process flows of a repulper

• Identify and describe the main components of a repulper

• Describe the consequences of improper level and consistency control in a repulper

• Explain the purpose of deflaking

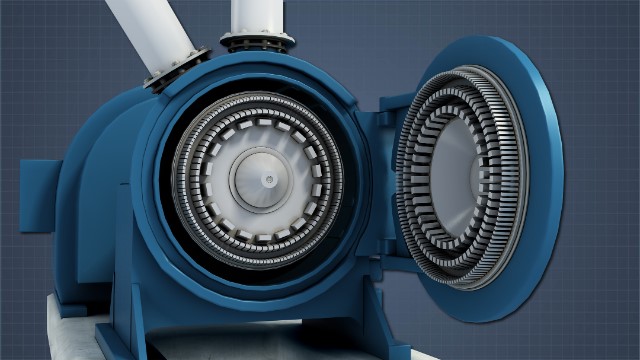

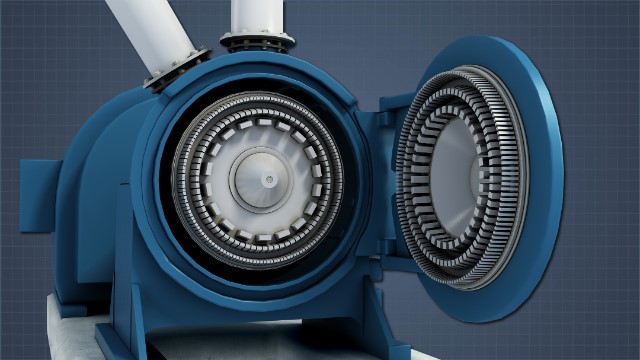

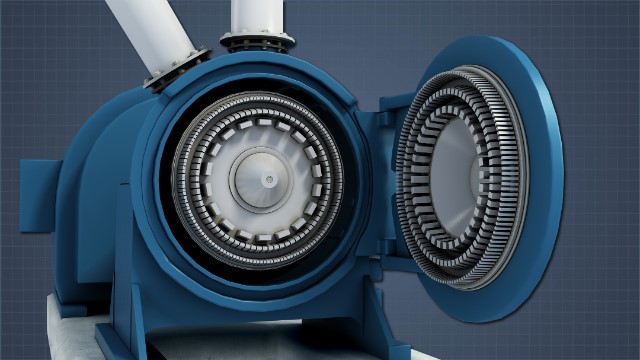

• Identify and describe the main components of a disk deflaker

• Explain the purpose of screening

• Describe the equipment and process flows in coarse screening and fine screening systems

• Identify and describe safety hazards and safety guidelines associated with repulping, deflaking, and screening equipment

Specs

Frequently Asked Questions

What is market pulp?

What is the difference between “pulping” and “repulping”?

What are important repulper operating variables?

What is “deflaking”?

What is the purpose of screening pulp?

Sample Video Transcript

Deflaking is sometimes necessary to break down fiber flakes that remain in the pulp slurry after repulping. Flakes result from the presence of size, coated, and wet strength grades in recycled fiber bales. Deflakers are similar to refiners in design and operation. Disc deflakers consist of one or two stationary discs and one rotating discs all fitted with slotted raised rings. The pulp slurry enters at the center of the discs and travels outward radially passing through the slots at the periphery. The acceleration and sheer forces present in the slots help break apart the fiber flakes. Heat and chemicals can be added to the pulp before deflaking to weaken the flakes and improve results. Very difficult to repulp grades may require two or even three deflaking stages.