March 4, 2013 4 min read

The 6 levels of DOT Inspections Explained

Industry:

Solution:

The Department of Transportation (DOT) requires commercial motor vehicles (CMV) with a weight of more than 10,001 pounds to undergo an inspection every year to make sure all parts are in good working order. There are six levels of DOT inspections which simply refer to which parts of the CMV and its driver will be inspected.

It should be noted that DOT Inspections are separate from the periodic vehicle inspections that must be conducted by the motor carrier. The six levels of a DOT inspection are:

Level I: North American Standard Inspection

Level I inspections are the most common and most thorough level of DOT inspections. During these checks, the DOT inspector looks at important documents, such as:

- the vehicle operator’s commercial driver’s license (CDL);

- the medical certificate confirming the operator passed their annual DOT physical exam;

- logbook records for the last 8 on-duty days to show hours of service records;

- and medical card or waiver, if applicable.

The inspector will also check for any signs of drug or alcohol use.

Finally, the professional conducting the evaluation will also inspect the vehicle’s seat belt, exhaust system, turn signals, tail lamps, headlamps, steering wheel, wheels and rims, and fuel system.

A Level I inspection typically takes between 45-60 minutes to complete.

Vector EHS Management Software empowers organizations – from global leaders to local businesses – to improve workplace safety and comply with environmental, health, and safety regulations.

Learn more about how our software can save you valuable time and effort in recording, tracking, and analyzing your EHS activities.

Learn more about how we can help:

- Incident Management Software →

- EHS Inspection Software →

- Key Safety Metrics Dashboard →

- Learning Management System (LMS) and Online Training Courses →

- Mobile Risk Communication Platform

Download our EHS Management Software Buyer’s Guide.

Level II: Walk-Around Driver/Vehicle Inspection

Level II inspections involve examining everything in the Level I inspection with exception of the parts that involve the inspector getting under the vehicle. This includes the documents reviewed under Level I inspections.

The Level II inspection takes about 30 minutes to complete.

DOT driver vehicle inspection checklists include vehicle items a driver should inspect on a day-to-day basis before and after driving the vehicle to be in compliance with DOT regulations.

To assist drivers in meeting DOT requirements, we’ve developed a pre-trip inspection DOT-compliant checklist that drivers can use to record their findings.

DOT-Compliant Driver Inspection Checklist

Download

Level III: Driver-Only Inspection

During this check, the inspector will take an in-depth look at the vehicle operator’s credentials. Drivers are checked for skill performance evaluation (SPC) certificate, driver’s license, medical certification, record of duty status (RODs), and seat belt usage. The inspector will also review any driver vehicle inspection reports signed by the driver.

Level III inspections commonly take about 15 minutes to complete.

Level IV: Special Inspection

Level IV inspections are one-time examinations that take a close look at a specific item. They are typically scheduled to either verify or invalidate a previous claim about a vehicle.

The time to complete a Level IV inspection will vary depending on the circumstances.

Level V: Vehicle-Only Inspection

Level V inspections look at everything specified under Level I. The only difference is that they are executed without the driver present. Part of this inspection involves checking the vehicle’s brake systems, steering mechanism, suspensions, and electrical cables.

Level V inspections can take up to 45 minutes to complete.

Level VI: Enhanced NAS Inspection for Radioactive Shipments

This inspection is used for certain radiological shipments. Select radiological shipments only comprise highway route controlled quantities set forth by DOT’s title 49 section 173.403.

The vehicle, drivers, and cargo must all pass this inspection before departing. The Level VI inspection will typically take up to 60 minutes to complete.

Once complete, a special nuclear symbol will be attached to the CMV to indicate it passed a Level VI inspection. This nuclear symbol is only valid for one trip and will be removed upon arriving at the destination.

Are you prepared for a DOT inspection?

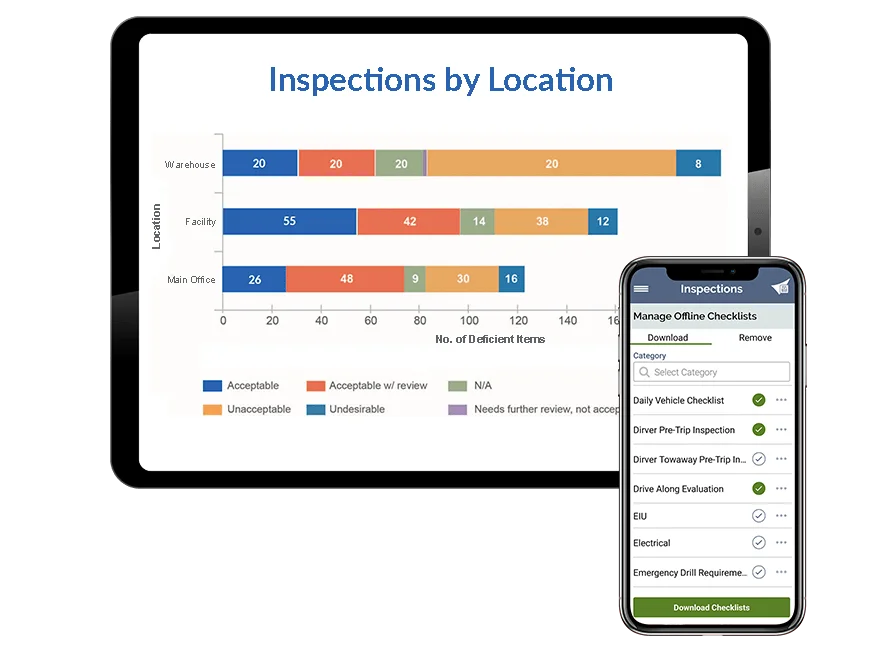

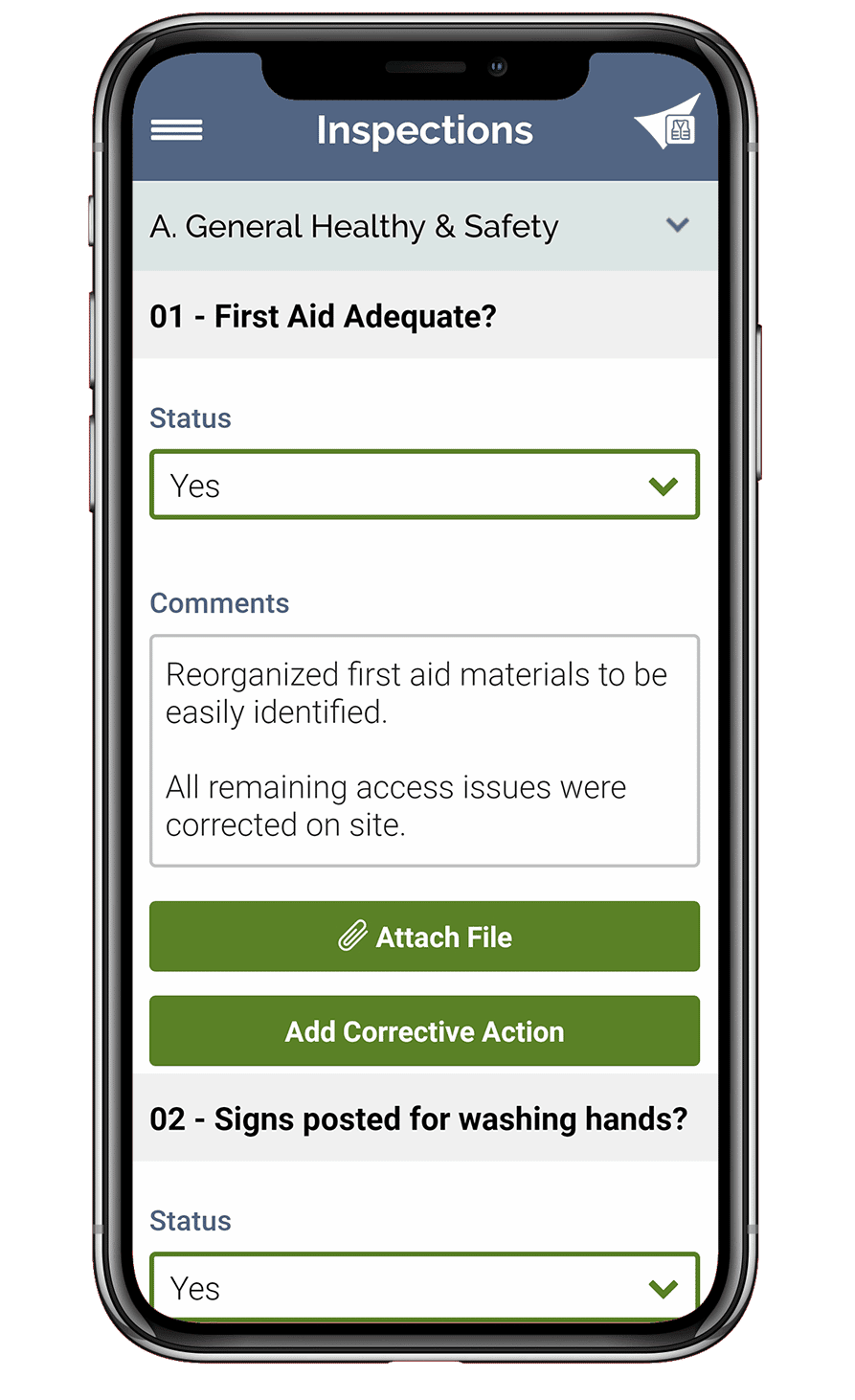

To conduct ongoing vehicle inspections for your organization, you may want to consider downloading the Vector EHS Management mobile app. This safety software enables you to conduct inspections in the field, allows you to use pre-built checklists, upload pictures, and can be used with or without internet access.