October 17, 2017

What To Expect from an OSHA PSM Investigation

Industry:

Solution:

OSHA's Process Safety Management regulation, also known as PSM, sets specific requirements for employers who use highly hazardous chemicals at the workplace.

And because these highly hazardous chemicals can lead to catastrophic events, OSHA takes the PSM regulation very seriously. Part of that seriousness includes rigorous PSM inspections at work areas covered by the PSM regulation.

Not so long ago, we sat in on a conference presentation about PSM inspections from Brandi Davis of Oregon OSHA. Ms. Davis is a Senior Health Compliance Officer (and Industrial Hygienist) with Oregon OSHA who performs PSM inspections and she's been kind enough to talk with us about what to expect during an OSHA PSM inspection. So if you're curious about this, go right ahead and read the rest of the article.

Also, please know we've included a free PSM compliance checklist for you at the bottom of this article in addition to the tips from the OSHA PSM inspector.

OSHA's Process Safety Management regulation, also known as PSM, sets specific requirements for employers who use highly hazardous chemicals at the workplace.

And because these highly hazardous chemicals can lead to catastrophic events, OSHA takes the PSM regulation very seriously. Part of that seriousness includes rigorous PSM inspections at work areas covered by the PSM regulation.

Not so long ago, we sat in on a conference presentation about PSM inspections from Brandi Davis of Oregon OSHA. Ms. Davis is a Senior Health Compliance Officer (and Industrial Hygienist) with Oregon OSHA who performs PSM inspections and she's been kind enough to talk with us about what to expect during an OSHA PSM inspection. So if you're curious about this, go right ahead and read the rest of the article.

Also, please know we've included a free PSM compliance checklist for you at the bottom of this article in addition to the tips from the OSHA PSM inspector.

- Learning Management Systems

- Online Safety and Health Training Courses

- Incident Management Software

- Mobile Safety Training Apps

PSM & OSHA PSM Investigations

With a quick additional thank you to Brandi Davis and Oregon OSHA, let's get right to the questions about PSM and PSM inspections by an OSHA inspector.Question: What is PSM?

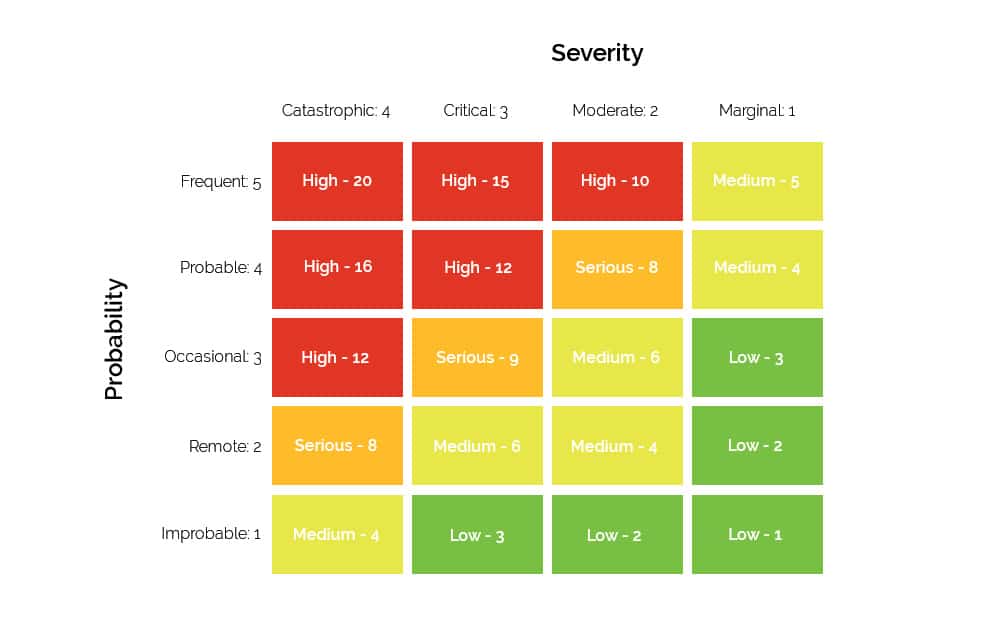

Brandi Davis: Let me give a technical answer first. PSM is Process Safety Management. It is a management system based on 13 elements that are designed to identify, evaluate, eliminate or manage the inherent risks of processes containing highly hazardous chemicals. Process Safety Management is a regulation found in Oregon OSHA’s rules under 1910.119. Employers are required to comply with Process Safety Management if they have quantities of highly hazardous chemicals in excess of the threshold quantities listed in the 1910.119 regulation. Now let me give a non-technical answer. Process Safety Management is a management system designed to understand the limits and weaknesses of a process. These processes have sufficient quantities of highly hazardous chemicals on site that a release could seriously impact the employees and the surrounding community. The purpose of the PSM management system is to ensure that the chemical tiger does not get out of the cage.Question: What is the history and purpose of PSM?

Brandi Davis: The history to PSM is a long one that is paved with numerous chemical catastrophes throughout the world. In general, most would agree that the birth of the process safety movement came after the 1984 Bhopal India Union Carbide event that released methylisocyanate and killed over 3000 people. A. few years later Union Carbide had another leak at a different facility that resulted in the deaths of over 100 people.. These fatal events triggered a heightened level of awareness to the hazards these processes pose to employees. In July of 1990, Federal OSHA proposed the PSM regulation and then after extensive public hearings and debate the PSM standard became effective in 1992. [optin-monster slug="tfb0ea1ze5dftije3pdk"]Question: How often are facilities inspected by OSHA?

Brandi Davis: I can only provide insight from Oregon OSHA operations. There is no specific answer to this question. In general Oregon OSHA sets annual goals for the number of PSM inspections to complete. Typically, this goal has been about 10 Process Safety Management inspections a year. There are four ways Oregon OSHA will enter into a facility in order to perform a Process Safety Management inspection. The first, is a PSM program planned (pro-active) inspection. This is where the employer number was selected from a randomized list of facilities with known quantities of a covered chemical on site. Second, is a complaint filed against an employer regarding some aspects of their PSM program. Third, is an accident at a facility with a covered process. The fourth is a referral from another agency or internally from a different compliance officer (without the expertise in PSM) that has identified some concern or hazard related to the PSM covered process. It is possible for a facility to undergo more than one PSM inspection in a short period of time. This is unusual, but possible. For example, Oregon OSHA received a complaint regarding a covered process and conducts an inspection to evaluate those complaint items. Then 6 months later a release at the facility results in the hospitalization of an employee, and Oregon OSHA conducts another PSM related inspection to evaluate the conditions that lead to the release.Question: As a PSM inspector, what are some of the things you look for every time?

Brandi Davis: This is difficult to answer. I will provide you with some general observations, but this is not to be taken as any absolute. Each PSM inspection is unique and the information can take the inspection in several different directions. But here are some things to consider:- First impressions go a long way. If the process is clean, organized, properly labeled, material is readily available and personnel seem knowledgeable the officer is taking notice/observing these things on the first walk of the process and with the provided responses to questions.

- Piping and instrumentation diagrams are almost always going to be evaluated on every PSM inspection, regardless of the types of PSM inspection (comprehensive, accident, complaint or referral).. The officer is going to look for the availability of the Piping and Instrumentation Diagrams and the accuracy and completeness of the diagrams.

- Standard operating procedures: Again, this element is evaluated almost every time a PSM inspection is completed. It is the SOPs that provide instructions to the employee and to the compliance officer regarding how things should be done at the facility. The SOPS are going to be evaluated for availability, accuracy, annual review, employee training on SOPs, and completeness of the SOP.

- Process Hazard Analysis (PHA): Officers are going to evaluate, at a minimum, the last two PHAs. This provides the officer with information regarding how well the system has been evaluated for possible failure modes. The officer is going to evaluate who participated in the PHA, the completeness of the PHA, the appropriateness of the PHA methodology used, the recommendations from the PHA and the documentation associated with the PHA.

- Recognized and Generally Accepted Good Engineering Practices: RAGAGEP: The officer is going to have to know which RAGAGEPS the facility has implemented to maintain the process. The officer is then going to test the facility’s compliance to those established RAGAGEPS.

Question: What are some of the most common problems companies face when trying to comply with PSM?

Brandi Davis: This is from my point of view as a compliance officer – looking from the outside in.- Resources – The facility has not provided sufficient resources to fully implement a PSM program. It is not uncommon to encounter a facility that spent a significant amount of money to hire an outside consulting company, that specializes in PSM to develop their PSM program. Then once the consultant company is gone, the program is turned over to the facility to implement. The facility does not properly identify the time commitments, the financial commitments or the personnel commitments to fully comply with the PSM program that was delivered to them by their consulting company.

- Understanding – The facility management team does not thoroughly understand the principals or goals of a PSM program. Without this understanding, it is difficult for a facility to embrace the management system and understand how each of the program’s elements are inner connected and rely on each element’s success for the entire management system’s success.

- Complacency – A facility can fall victim to believing that once they have implemented their PSM program, that the level of engagement in the program can decline. A PSM program should be a living program that is in a constant state of development. The principals of PSM call for facilities to constantly evaluate their process, their operating limits, their protocol training, their maintenance programs, their management of changes to the system, etc. Too often a facility’s PSM program will wane or falter after 7 years. Facility personnel get complacent about performing a recertification of the Process Hazard Analysis or personnel get complacent about completing the management of change process for something they see as a minor change in the system or personnel get complacent about reviewing a standard operating procedure that they have reviewed 7 times before.

Question: What happens if you find a problem at a facility?

Brandi Davis: The simple answer is that a citation is issued to the facility. Let me explain this response. It is rare that a problem at a PSM facility is a simple isolated event that does not impact or is not connected to another one of the 13 elements of the PSM program. Oregon OSHA’s perspective on “problems” at a PSM facility is that they generally are considered serious in nature, when you realize that the highly hazardous chemical can be impacted because of the “problem." [optin-monster slug="qcvrebwht4yyrxwo3vqp"]Question: What resources are available to help companies comply with PSM?

Brandi Davis: Oregon OSHA offers every employer in the State of Oregon access to our consultative services. A facility can request an evaluation of their PSM program by a trained consultant without fear of receiving citations for their deficiencies. Here are some other helpful resources:- Chemical Safety Board – they offer a number of training resources about lessons learned from past chemical release events that may be relevant to covered facilities.

- Center for Chemical Process Safety – CCPS

- The American Institute of Chemical Engineers (AIChE)

- Worker's comp insurance carriers. A facility’s workers compensation insurance carrier is also a great resource for evaluating the hazards associated with a chemical process.

- Trade and industry groups. If the facility is in an industry with industry/trade associations. Industry groups tend to all need to the same types of chemicals and thus have a tendency to have PSM facilities as members of their trade associations.

- Third party consultation groups. There are consultation groups that specialize in PSM programs and the hazards associated with certain facilities. These consultants can be very valuable in development of a PSM program and the maintenance of an existing program.

- The Internet. There are a number of PSM blogs or groups on the internet. There are PSM groups in LinkedIn and other social media forums.

Question: What are suggestions you would offer to companies trying to comply with PSM?

Brandi Davis: Utilize a variety of the resources listed above to develop, implement and maintain your PSM program. Trying to piece together a PSM program without the needed information or expertise is often a fruitless process.Question: Any special thoughts for manufacturers of pulp, paper, tissue, or corrugated board?

Brandi Davis: Most of these facilities are well educated about the PSM regulation and have implemented a PSM program at their facilities. My thoughts for them or recommendations for this industry – fight complacency. In addition, I would recommend these facilities adopt a combustible dust program into their PSM programs. [optin-monster slug="wqhlhsrtzmkopgekqqkp"]Conclusion: PSM Investigations by OSHA

We hope that answered all or at least many of your questions about OSHA PSM inspections. Let us know if you've still got any questions. You might also find these other PSM-related articles interesting:- Facing the Challenges of PSM, an Interview with ASSE's Safety Educator of the Year

- What to Know about PSM, an(other) Interview with Brandi Davis of Oregon OSHA

- New OSHA PSM Compliance Guidelines for Small Businesses

- PSM Overview Video by RedVector

- Free PSM Compliance Checklist

- Convergence Training|RedVector Expanded PSM Online Training Solutions

Process Safety Management Compliance (PSM) Checklist

Here is a checklist to help your process safety management compliance.

Download Free ChecklistExplore our software solutions designed to help your organization succeed

Request a Demo