Wood Properties and Chip Quality Testing

Wood is the main source of the fibers used in the large-scale industrial production of paper-based products. Paper can be made from other plant fibers such as papyrus, cotton, and flax, but wood has much greater availability. The various characteristics of these plant fibers help develop the properties of different paper products. This course describes the sources of fibers, the various characteristics of these fibers, how they are tested, and their value or impact in the manufacturing of pulp and paper.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Differentiate between “earlywood” and “latewood” fibers with regards to pulp properties

• Differentiate between “heartwood” and “sapwood,” including the impact on the pulping process

• Differentiate between hardwood and softwood in regards to wood composition, pulping, and pulp properties

• Identify and describe key chip quality parameters, associated testing, and the impact on the pulping process

• Identify and describe woodyard safety hazards and guidelines

Specs

Frequently Asked Questions

How do tree growing conditions affect chip properties?

What are some important chip quality parameters?

What are some properties of softwood fibers?

What are some properties of hardwood fibers?

What are the different chip size categories?

Sample Video Transcript

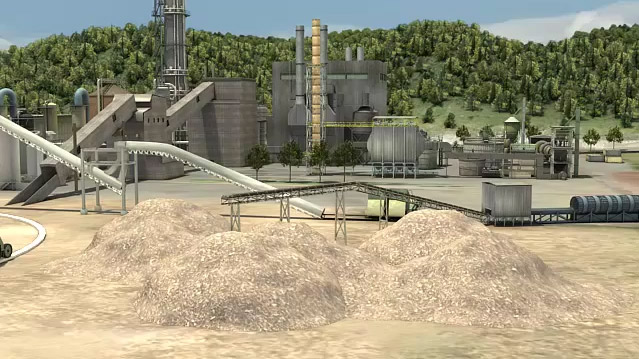

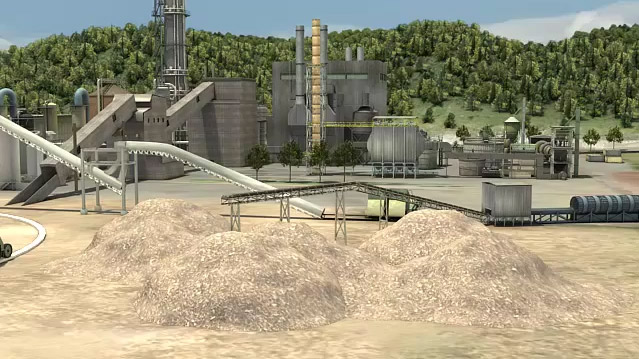

Wood is the main source of the fibers used in the large scale industrial production of paper-based products. Paper can be made from other plant fibers such as papyrus, cotton, and flax but wood has much greater availability. Wood fibers come from many different regions and have unique characteristics based on the tree species and the climate they grow in. The various characteristics help developed the properties of different paper products. For example, tissue paper utilizes the soft feeling from thin, flexible eucalyptus fibers, while cardboard boxes are made of strong, bulky stiff fibers like Douglas fir. Pulping breaks down wood chips into individual fibers. The Kraft pulping process uses digestors to process wood chips at high temperature and pressure with a strong acolyte.