Box Plant Basics – Other Box Plant Equipment

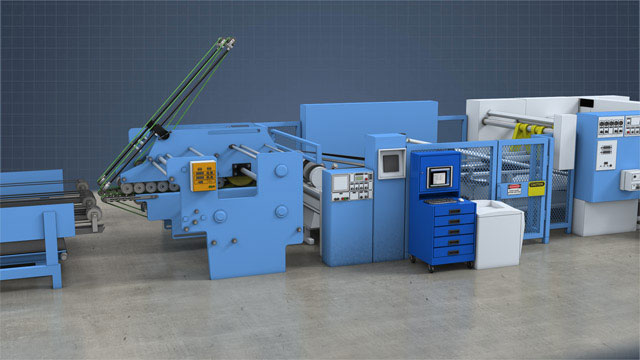

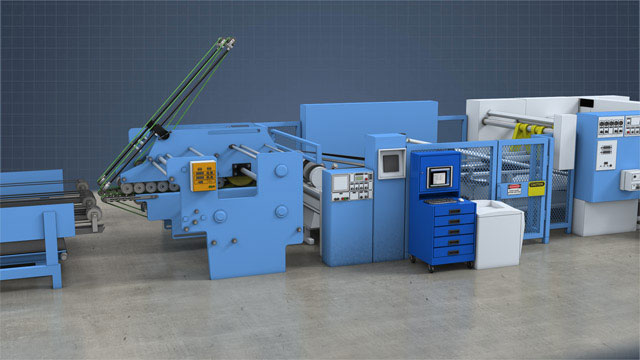

To convert a piece of corrugated board that is produced on a corrugator into a box, the sheet of board must be cut, slotted, and scored into a “box blank” (the precursor to a box). Many boxes are also printed, folded, and glued before they are shipped to the customer, and some boxes are stitched, taped, or labeled, or have specialty forms and materials inserted, before they leave the box plant. This module discusses the basic operation of several converting and finishing machines that can be found in box plants, including printer-slotters, folder-gluers, stitchers, tapers, laminators, litho-laminators, presses, bundlers, and palletizers.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

•Describe corrugated board and box plant operations •Define corrugated board reference terms •Describe the design and operation of box plant equipment, including printer-slotters, folder-gluers, stitchers, tapers, laminators, presses, litho-laminators, bundlers and palletizers

Specs

Frequently Asked Questions

What types of products are typically produced by printer-slotters?

What are folder-gluers used for?

What are stitchers and tapers used for?

Which pieces of equipment are used to join together two or more sheets of board to create thick board products?

How are high quality graphics added to corrugated board products?

Sample Video Transcript

Folder-gluers can be used to convert the flat box blanks from printer-slotters and die-cutters into folded and glued box blanks. First, a hot melt or cold adhesive is applied to the glue tab or fourth panel. Then, various devices, rods, belts, rails, etc. are used to fold each box blank along its scores. Join the glue tab to the fourth panel and create the manufacturer’s joint. Finally, the folded box blanks are counted and stacked.