Broke Repulpers

Broke is an important byproduct of the papermaking process that is reclaimed and recycled back into the furnish. Broke is generated at various points around a paper machine and so repulpers are positioned in both under-machine and off-machine locations to collect, repulp, and pump the broke back to the stock system for reuse in the paper or board making process. This course covers the safety hazards around broke repulpers, off-machine repulper designs, the broke repulping process, as well as repulper consistency control.

Request a demoCourse Details

Learning Objectives

• List safety hazards and safety guidelines associated with broke repulpers • Identify and describe the major components of an off-machine broke repulper • Identify and describe primary process flows • List common sources of broke and methods of broke delivery to off-machine broke repulpers • Describe why it is important to control broke consistency and vat level in a broke repulper

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

List some common sources of broke to off-machine broke repulpers.

Trim and waste from converting operations, loose dry broke, and broke rolls that have been cut down by a guillotine.

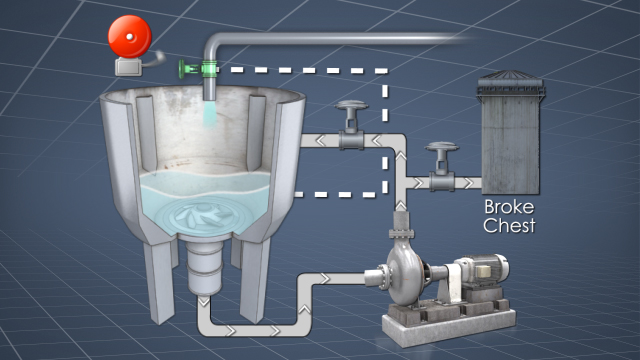

What are the major components of an off-machine broke repulper?

A vat, one or two driven agitators or rotors, an extraction plate at each rotor, one or more pumps, piping, and consistency and level controls.

How is broke typically fed to off-machine broke repulpers?

By blowers, fork trucks, and/or belt conveyors.

How is consistency typically controlled in an off-machine broke repulper?

A consistency control loop utilizes a signal from a consistency transmitter on a recirculating stock line to adjust dilution water flows to the vat and pump suction in order to maintain the consistency at or near a setpoint.

How is the vat level typically controlled in an off-machine broke repulper?

A level transmitter on the vat sends a signal to a level controller which controls an automatic makeup water valve position.

Sample Video Transcript

Off-machine broke repulpers typically process loose broke, converting trim, or waste, or cut down broke rolls. The broke may be fed into the repulper via blowers, belt conveyors, or fork trucks depending on the repulper location. Off-machine repulpers are typically used for batch processing of broke. In these installations, the repulper is filled with water and dry broke, agitated until it has been properly slushed at the desired consistency, and then drained by a pump.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.