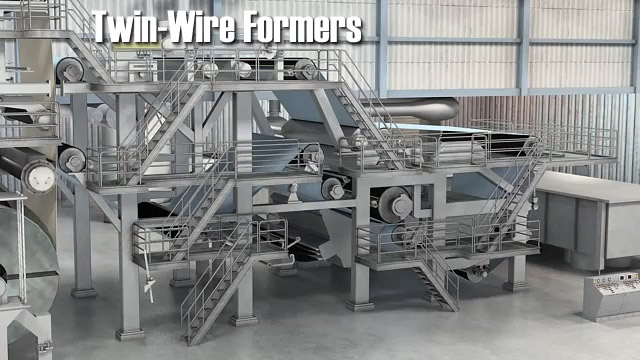

Paper Machine Twin-Wire Formers

A twin-wire former captures the stock jet in the converging nip formed between two fabric-covered rolls. These are also sometimes referred to as “gap” formers. There are four types of twin-wire formers – blade, roll, hybrid and roll/blade. Each has its own challenges and strengths. With twin-wire formers, it is especially important to define the desired sheet properties, and then work with equipment and fabric suppliers to configure, control and operate the design that is selected.

Request a demoCourse Details

Learning Objectives

• Identify the issues which led to the development of twin-wire formers • Identify and describe the four basic types of twin-wire formers, including blade formers, roll formers, hybrid formers and roll/blade formers • List advantages and disadvantages for each type of twin-wire former • Describe the challenges presented by twin-wire formers • Describe the advantages of twin-wire formers

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.