Pressure Screens

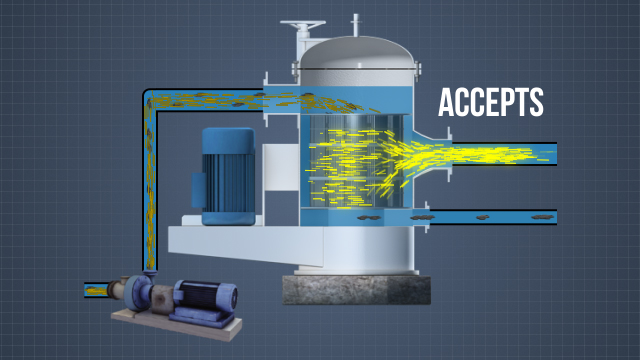

Pressure screens are used primarily to separate unwanted debris or contaminants from the desirable fibers in papermaking pulp. This is accomplished by flowing a pulp slurry over a surface that has many small holes or slots in it. Most of the small flexible fibers pass through the openings, and are accepted, and the larger particles which cannot pass through the openings are held back, or rejected. A typical pressure screen consists of a vertical cylindrical housing that contains a perforated cylindrical screen basket. Within the basket is a spinning rotor which supports foils or protrusions that run close to the surface of screen. Screen performance is quantified by looking at such factors as the reject rate, debris removal efficiency, and long fiber reject rate. [course outline] Pressure Screen Internal Construction Pressure Screen Baskets Pressure Screen Rotors Screening Theory 1 of 2 Screening Theory 2 of 2 Screen Performance 1 of 2 Screen Performance 2 of 2 Multiple Stage Screening Systems Pressure Screen Control Pressure Scre

Request a demoCourse Details

Learning Objectives

Explain the purpose of pressure screening Identify the major components of a cylindrical pressure screen Describe how screens are kept from plugging Describe why screening systems use multiple stages List three measures of screening performance Identify controls which affect screening performance List possible causes for pressure screen process and mechanical malfunctions

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What is the primary purpose of a pressure screen?

The purpose of a pressure screen is to separate unwanted debris from desirable fiber in a pulp stream.

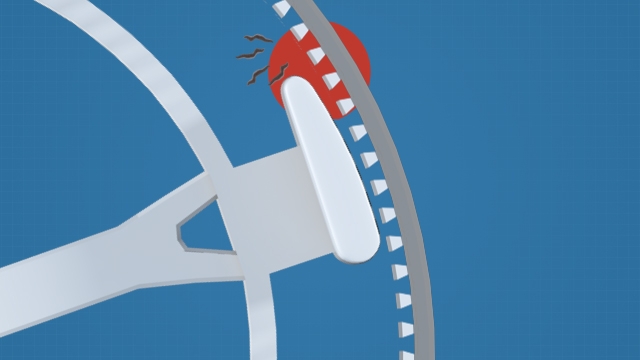

What is the purpose of the spinning rotor in a pressure screen?

The purpose of the spinning rotor within the screen basket of a pressure screen is to keep the screen clean and increase the flow of fiber through the screen.

What advantage is gained by using cascaded screens?

No separation process is perfect. Some good fiber is rejected with the unwanted debris in a pressure screen. Rescreening the rejected fiber permits the recovery of the good fiber. Rescreening multiple times is referred to as “cascading” screens, and ensures a high fiber recovery rate.

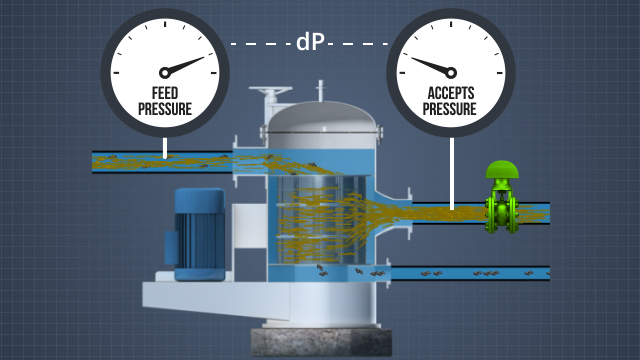

What is a good strategy for unplugging a pressure screen?

A plugged screen can often be unplugged by reducing or stopping the accepts flow, giving the basket an opportunity to clear itself through the rejects line, and re-opening the accepts valve.

What could be some causes of poor accepts quality?

There are many potential causes of poor accepts quality, but some of the more common possibilities are: low reject rate, a hole or gap in the screen basket, unusually high level of contaminants in the feed or worn slots or holes in the basket.

Sample Video Transcript

A typical pressure screen consists of a vertical cylindrical housing which contains a perforated cylindrical screen basket. Within the basket is a spinning rotor which supports foils or shaped bumps that run close to the surface of screen. There are several variations on this design. Some screens are horizontal. Some designs have the inlet flow going to the inside of the basket, some have it going to the outside. One design employs two baskets with the flow being introduced between them. For simplicity, the rest of this module and the illustrations shown will refer to the “typical” screen described above with the feed flow going to the inside of a single basket.

Additional Resources

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.