Valve Common Problems

Although every valve and piping system is unique, some common conditions that exist are pressure drops and high fluid velocities. These conditions are not necessarily bad, and may even be part of the system design. This module will explain the causes and possible solutions of common problems resulting from these conditions.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

By the end of this course, you will be able to:

- Describe pressure drop and the problems associated with pressure drop

- Describe flashing and solutions for flashing

- Describe cavitation and the negative effects of cavitation

- Define “choked flow”

- Explain how turbulence can occur and ways to reduce turbulence and its effects

- Describe how to eliminate high noise levels in valves and piping systems

Specs

Frequently Asked Questions

What is pressure drop?

What is flashing?

What is cavitation?

What is choked flow?

What can cause turbulence to occur?

Sample Video Transcript

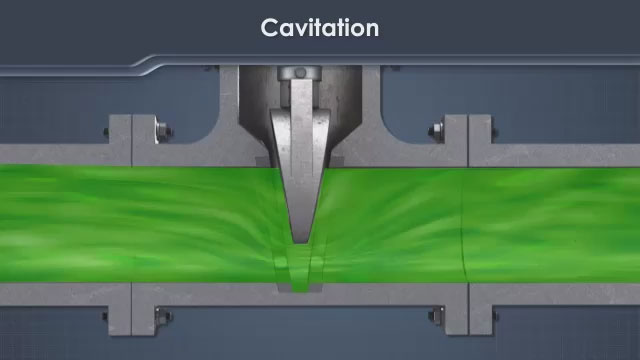

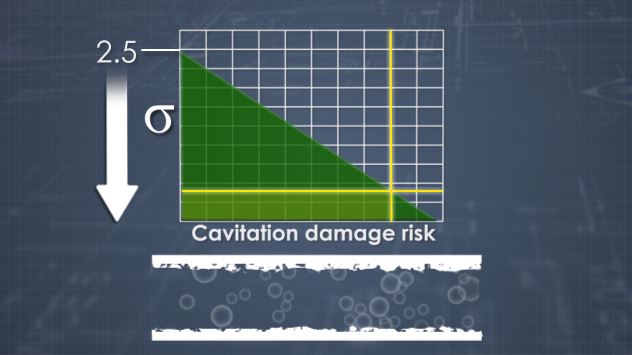

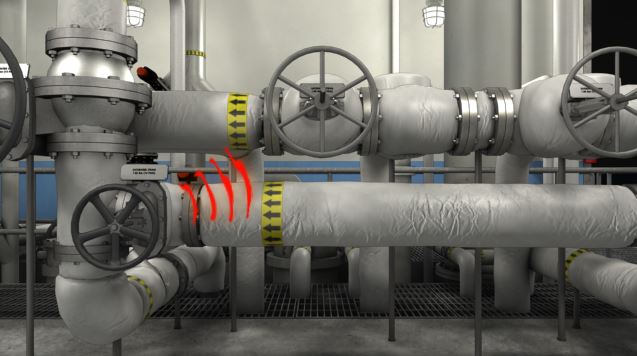

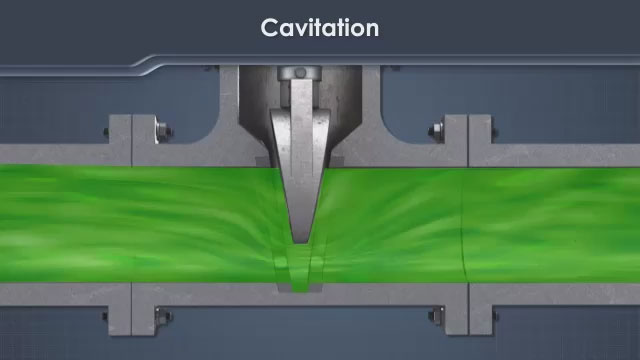

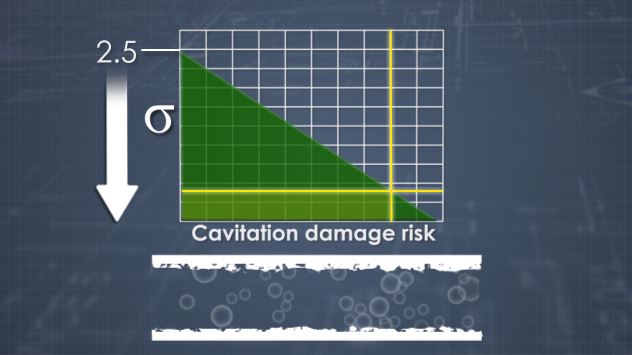

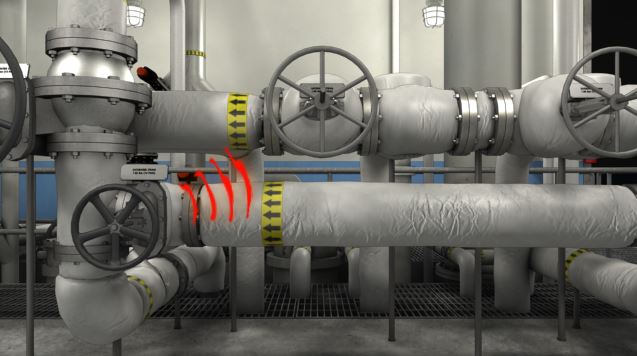

Cavitation and flashing begin in a similar manner. When a fluid passes through a restricted port valve and the downstream pressure is low enough, flashing occurs. After flashing, the pressure begins to recover. If the pressure increases high enough, some or all of the bubbles implode. The implosion of vapor bubbles is known as cavitation. It is often possible to hear cavitation in a system. The early stages of cavitation create a cracking or popping noise or may sound like rocks flowing down the pipe. Later stages may create a steady sizzling or hissing sound.