November 8, 2016 9 min read

Common hazards food processing industry workers encounter

Industry:

Solution:

Occupational Hazards in the food processing industry

Employees in the meat or food processing industries face numerous health and safety hazards on the job. Some of these many risks include:

1. High Noise Levels

The machines utilized in the food processing industry often operate at high noise levels, require frequent wash downs, and can be more susceptible to mold and vermin. The combination of these factors may make high noise levels more challenging to re-mediate than in other industries.

2. Ergonomic

Like many jobs requiring repetitive motion, workers in the food processing industry may be susceptible to musculoskeletal disorders.

3. Slips, Trips, and Falls

Again the frequent wash downs required by the food processing industry create slippery surfaces that put workers at risk for slips, trips, and falls.

4. Chemical

Food processing workers routinely utilize chemical soaps, detergents, sanitizers, and disinfectants to help keep food free of unwanted microorganisms and other contaminants. Food processing also uses refrigerants such as ammonia which can be highly dangerous even in small quantities.

5. Dangerous Equipment

The machinery utilized for food processing can place workers at risk for amputations or other injuries unless organizations focus on ensuring proper machine guarding and Personal Protective Equipment (PPE)

6. Biological Hazards

Unique to poultry processing, workers may be exposed to biological hazards associated with handling live birds or exposures to dust and feces.

Additionally, stressful, fast-paced work environments can lead to accidents of varying degrees of severity. For more detail on general manufacturing hazards check out our popular top five hazards in safety manufacturing blog post.

Numerous organizations throughout the food processing industry rely on Vector EHS Management Software to improve workplace safety.

Vector EHS Management Software empowers organizations – from global leaders to local businesses – to improve workplace safety and comply with environmental, health, and safety regulations.

Learn more about how our software can save you valuable time and effort in recording, tracking, and analyzing your EHS activities.

Learn more about how we can help:

- Incident Management Software →

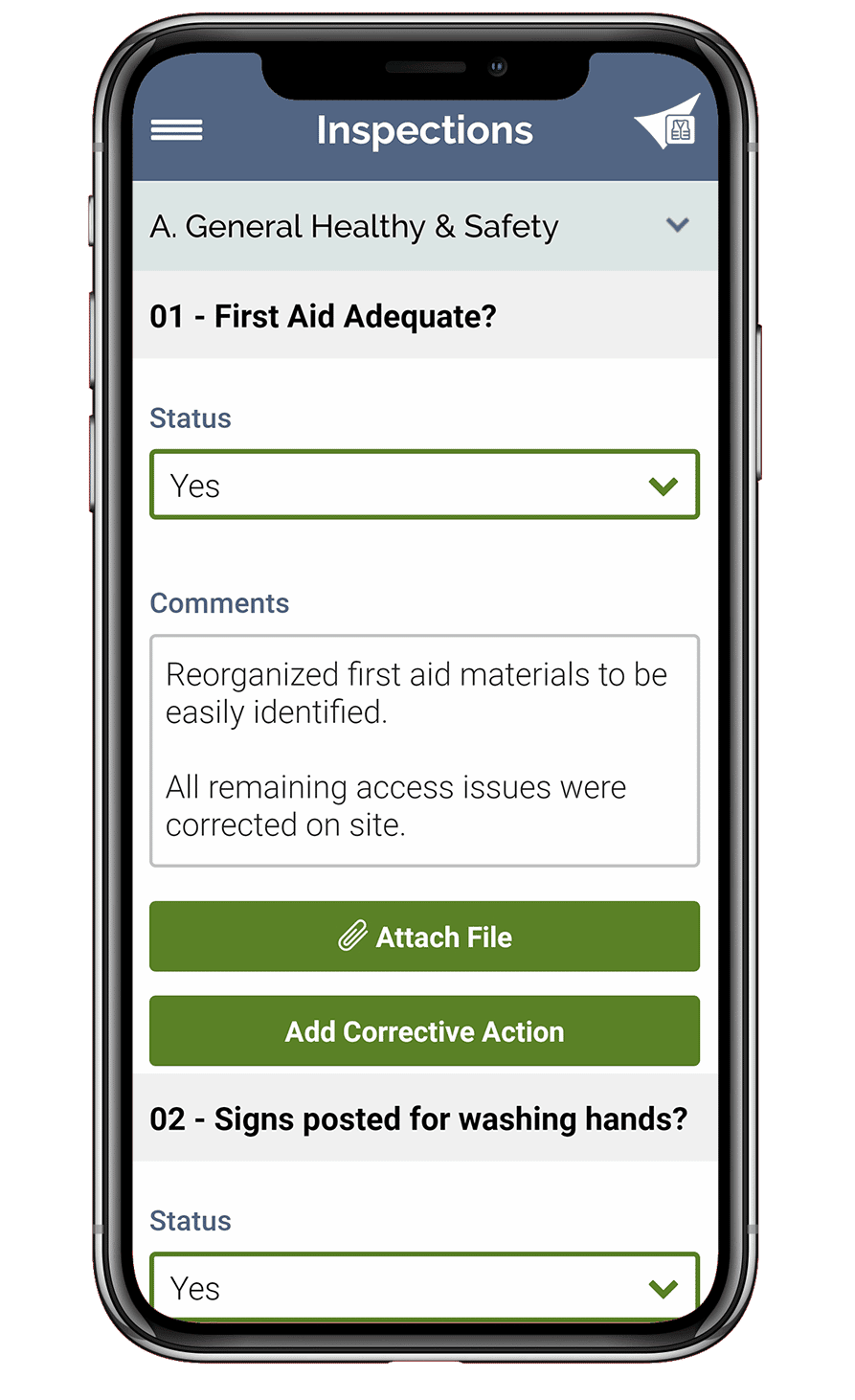

- EHS Inspection Software →

- Key Safety Metrics Dashboard →

- Learning Management System (LMS) and Online Training Courses →

- Mobile Risk Communication Platform

Download our EHS Management Software Buyer’s Guide.

Hazard Controls for these Risks

To protect their workers from harm, employers are required to establish engineering controls for dangerous equipment, safety, and emergency response programs. They also must make proper personal protective equipment (PPE) readily available for any employee who will be working in a dangerous area or operating heavy machinery and train their employees on the applicable PPE. Other controls include maintaining walking/working surfaces to prevent slips, trips, and falls, machine guarding, and ergonomics programs.

Employers should also provide appropriate training to their employees in the food processing industry. Common training for food processing industry workers includes:

- Personnel Protective Equipment

- Hazards of extreme temperatures (hot and cold);

- Incident Investigation;

- and Material Handling in compliance with OSHA’s Hazard Communication Standard (especially for the chemicals listed above).

In addition to training, food safety professionals can also hold regular toolbox talks to brief workers on the hazards that they may encounter while performing their daily tasks.

Employers endangering their workers at food processing facilities

“Employees in food processing industry face health and safety hazards.”

Despite the dangers facing food processing workers, employers around the country still fail to adequately protect them from select hazards and harm. For example, earlier this year, OSHA officials issued four serious and one other-than-serious safety violations to one of the nation’s leading suppliers of frozen specialty foods. The company faced more than $172,000 in proposed penalties following incidents where two workers at one of its facilities suffered amputations, while a third experienced lacerations and burns.

“Three women’s lives were dramatically altered because their employer failed to protect them from hazardous operating machinery parts,” said Judy Freeman, OSHA area director in Wichita. “Each year, thousands of workers like these suffer amputation and other injuries that are preventable when basic safety guards are in place and proper procedures are followed. [The company] needs to protect [its] workers, and [it] need to do it now.”

Later this year, OSHA officials found several safety and health deficiencies during an investigation at a Massachusetts facility for the country’s fourth-largest food service distributor. The company faced six serious and two repeated violations, amounting to $72,000 in fines. These hazards include an inadequate emergency response plan, failed ammonia sensor alarms and an ammonia leak.

“The leak was relatively small but the consequences could have been enormous,” Kenneth Shedden, OSHA’s area director for Boston and southeastern Massachusetts, explained. “Exposure to even as little as 300 parts per million of anhydrous ammonia is immediately dangerous to life and health. An uncontrolled release can be lethal and catastrophic.”

Vector Solutions can help employees manage the risks and hazards associated with food safety with our hazard and job safety analysis modules, exposure and chemical risks with our Industrial Hygiene monitoring software, and provide applicable employee training for food safety processing with our training content. Contact us to learn more about our safety management software.