November 12, 2023 1 min read

Guide to Behavior Based Safety (BBS)

Industry:

Solution:

What is BBS in Safety?

Behavior-Based Safety (BBS), also known internationally as Behaviour-Based Safety (BBS), is an approach to workplace safety that focuses on observing, analyzing, and modifying the behaviors of employees to prevent accidents and improve overall safety performance. This methodology recognizes that human behavior plays a crucial role in workplace safety and seeks to create a safety culture by addressing and influencing individual actions.

Behavior Based Safety Program: Key Components

A successful behavior-based safety program usually includes:

- Observations – Regular peer-to-peer observations to identify safe and unsafe behaviors.

- Checklists – Structured tools that standardize what to look for during safety observations.

- Feedback loops – Immediate feedback to reinforce safe practices and correct unsafe actions.

- Training – Ongoing behavior-based safety training to keep employees engaged and knowledgeable.

- Data tracking – Recording and analyzing observation data to identify trends and measure progress.

The Basics of a Safety Observation

When implementing a BBS program, observers (employees trained to conduct on-site safety reviews) conduct reviews of other employees with an eye on their behavior. These observers record safe and unsafe behaviors, in addition to noting safe and unsafe workplace conditions. The observer then shares the findings with the worker and provides feedback. Positive feedback is encouraged. Discussing the ways in which employees can perform their tasks in a safer manner helps workers and observers to become more aware of their behavior. BBS programs are based on a continuous feedback loop where employees and observers provide input on improving safety to each other and safety professionals utilize the data collected in conducting the observations to continually improve the BBS program.

The Behavior Based Safety Checklist

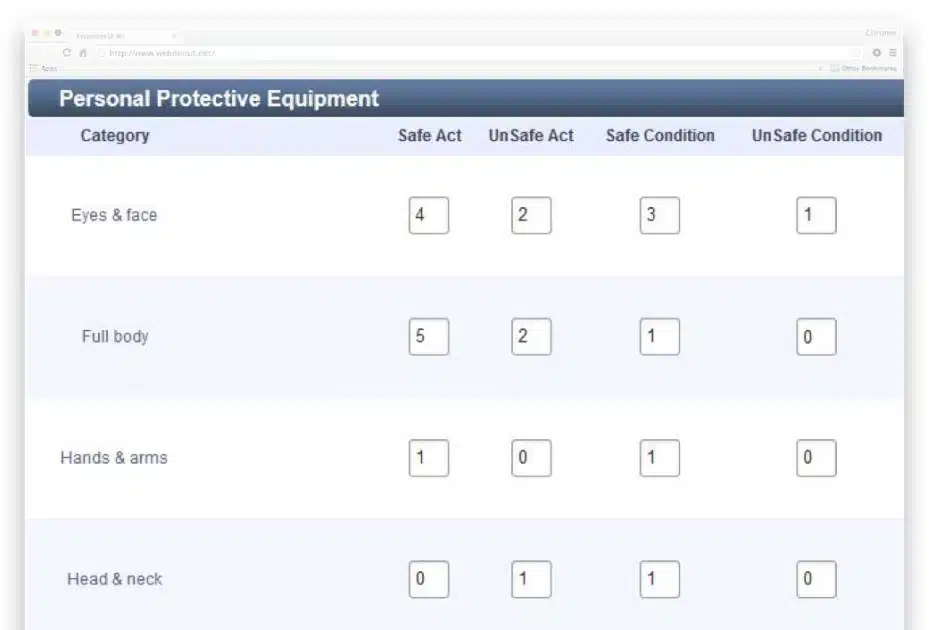

Organizations that implement a BBS program determine the appropriate list of behaviors to observe based on the unique behaviors and risks of their organization. Safety professionals usually develop a checklist format that is easy and quick for observers to complete in the field and lists the target behaviors.

For example, for organizations that operate a vehicle fleet, you might develop a behavior based safety checklist focused on common driver behaviors, such as the use of seat belts or signals. Checklists often include the basics of the observation (time, date, location, behaviors observed, observer) and the number of safe and unsafe observations of the reviewer. The checklist also includes fields for any feedback and comments provided to the employee.

Need help developing your checklist? We’ve put together a sample!

Sample BBS Checklists

Download

An example behavior based safety observation checklist

Based on your BBS goals and objectives, you might also create a schedule that determines how many observations (and what type of observations) should be conducted throughout your organization on a weekly, monthly or quarterly basis. Schedules and observations can change based on the continuous feedback loop of a BBS program.

However as observation checklists and schedules become more in-depth, they also become harder to track and manage. You may want to turn to technology to improve the management of your BBS program without sacrificing its effectiveness.

Does OSHA require a Behavior Based Safety program?

OSHA does not specifically require organizations to implement a behavior based safety program. OSHA however has recommended practices for safety and health programs that include the involvement of employees and managers in safety and hazard identification and assessment. A strong BBS program assists organizations in achieving these safety goals by allowing for multiple opportunities for employees and managers to be involved in the safety process and to assist in assessing and identifying hazards.

BBS Safety Frequently Asked Questions

What is BBS?

BBS, or Behavior-Based Safety, is a process that improves workplace safety by focusing on employee behaviors and reinforcing safe actions.

Does OSHA require BBS?

No, OSHA does not specifically require a BBS program. However, OSHA encourages proactive safety efforts, and BBS can support compliance by reducing unsafe behaviors.

How do you know a BBS program is working?

A successful BBS program shows fewer at-risk behaviors, improved safety culture, and measurable reductions in incidents and injuries over time.

How do I know that my Behavior Based Safety program is working?

Measuring the effectiveness of BBS programs can be tricky and require constant and real-time review of the observation data collected by your observers. Organizations focus on analyzing observation metrics such as percent safe (the number of safe observations divided / by the total number of observations conducted) with the goal of increasing the number of percent safe observations. Safety professionals look to then reduce unsafe behaviors by targeting behaviors with a high unsafe percentage and developing applicable training and/or other programs to change this behavior.

Organizations also often look at their incident rates with the goal of reducing their incident rate as their percentage of safe behaviors increases. In addition, organizations also conduct surveys and interviews to determine the impact that BBS programs can have on safety culture and /on employee morale.

Our behavior based safety software also offers lots of time-saving techniques to help you track and analyze your observation data. To learn more about how Vector EHS Management software can assist you with recording and tracking employee behaviors contact us today.

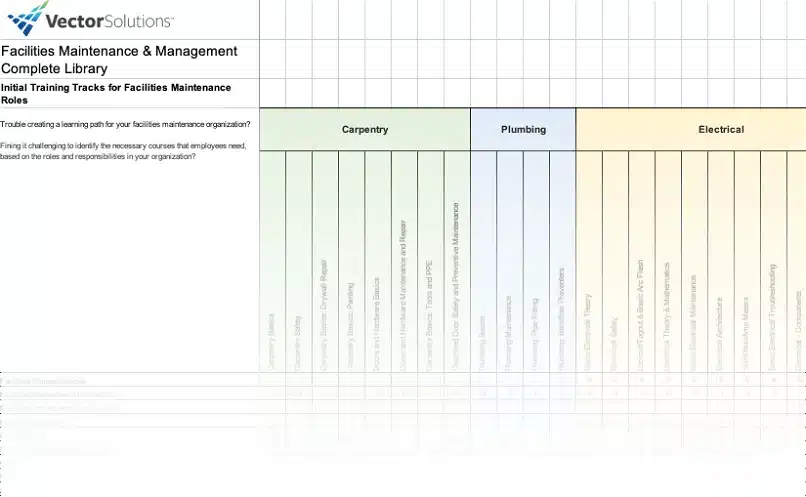

Facilities Maintenance Kick-Start Smart Guide

Download