Alkaline Extraction

Chlorine is an excellent chemical for pulp bleaching because of its low cost and lignin removal effectiveness. For these reasons, chlorine was traditionally used in the first bleaching stage to remove up to 90% of the lignin remaining in unbleached pulp. Chlorination is the treatment of pulp with chlorine to solubilize lignin and ultimately bleach the pulp. This course discusses the basics of chlorine bleaching chemistry, the purpose of extraction, and the equipment used in chlorination and extraction.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Define the purpose of extraction

• Describe the variables of extraction

• Describe the safety concerns of sodium hydroxide

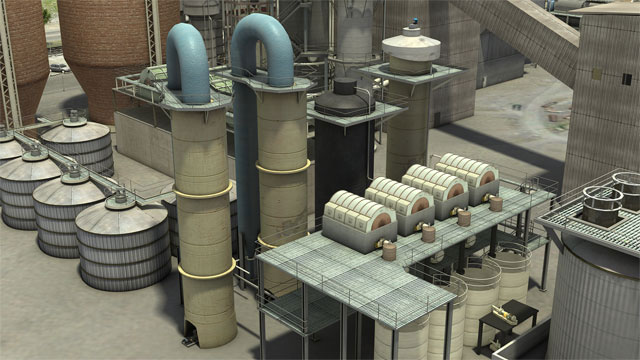

• Identify equipment used for extraction

• Describe the role of oxygen and hydrogen peroxide in extraction

Specs

Frequently Asked Questions

What is an alkaline extraction stage?

What chemicals are used for alkaline extraction?

Why are oxygen and/or hydrogen peroxide added to an alkaline extraction stage?

What is the retention time for alkaline extraction?

What are some of the hazards of sodium hydroxide?

Sample Video Transcript

Chlorination is the treatment of pulp with chlorine to solubilize lignin and ultimately bleach the pulp. Chlorine is an excellent chemical for pulp bleaching because of its low cost and lignin removal effectiveness. For these reasons, chlorine was traditionally used in the first bleaching stage, to remove up to 90% of the lignin remaining in unbleached pulp. Chlorine is a forgiving bleaching chemical. The reaction is fast and can occur over a wide range of pH, temperature, and consistency. Chlorine use is almost completely obsolete because it harms the environment. Only a few locations around the world still use elemental chlorine for bleaching. Chlorine makes lignin soluble in water or in alkali. So an alkaline extraction stage is required after chlorination to actually remove the lignin from pulp.