HAZWOPER Air Monitoring

Airborne contaminants present the greatest danger to hazardous waste and emergency response workers. Air monitoring is required to identify and quantify airborne hazards, so appropriate protective measures can be implemented. An air-monitoring plan must be included as part of a site-specific Health and Safety Plan (HASP). This module will discuss the requirements of an air monitoring plan, the sensors used to detect hazardous conditions, and what actions should be taken based on monitoring results.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

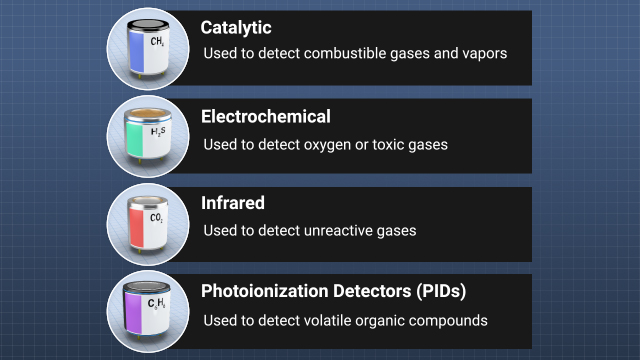

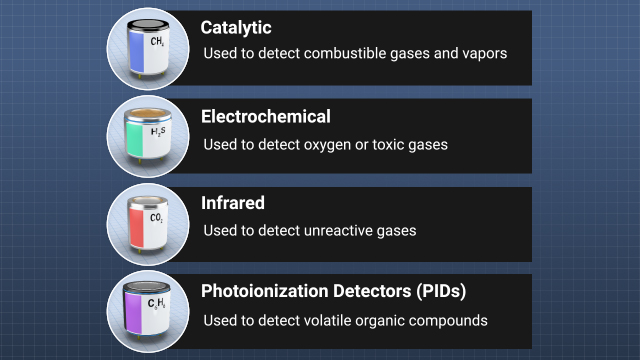

• Describe the purpose of an air monitoring plan • List and describe air monitoring requirements • Describe the different units used to measure gas and vapor concentrations in air • Describe the uses of common gas sensors • Define the different instrument calibration methods • List the action limits for combustible gas, oxygen, and toxic gas concentrations

Specs

Frequently Asked Questions

What is the purpose of air monitoring?

What are direct-reading instruments?

What is the difference between %, ppm, mg/m3?

What is a multi-gas detector?

What is the difference between a bump test and a calibration check?

Sample Video Transcript

Air monitoring is a required at hazardous waste sites and during incidents involving hazardous materials to protect the safety of workers and the public. The air needs to be tested to identify and quantify all airborne hazards. This involves testing the atmospheric concentrations of oxygen, combustible gases, and toxic gases. Different sensors are used to test for different gases. Multi-gas meters are popular because they combine multiple sensors into one instrument. The key to maintaining a safe work environment is maintaining and calibrating the gas detection equipment, so they work properly and measure accurately.