Paper Machine Thermocompressor Steam Systems

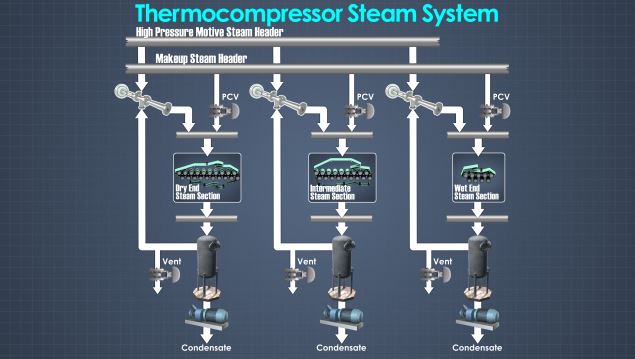

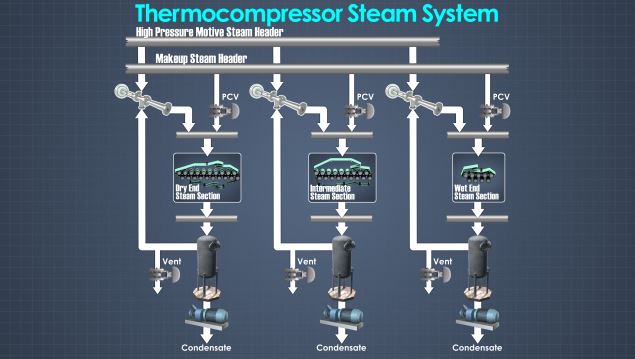

Paper and board machines use steam-heated dryer cylinders and multiple steam groups to dry the sheet to its final moisture target. In a thermocompressor steam system, each steam group has a thermocompressor that uses high pressure motive steam to pull flash and blow-through steam from the section condensate tank and boost it to a more useful pressure. This steam is supplied to the section steam header where makeup steam is added to control the steam pressure going to the cans. This module will cover the components and operation of a thermocompressor steam system.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

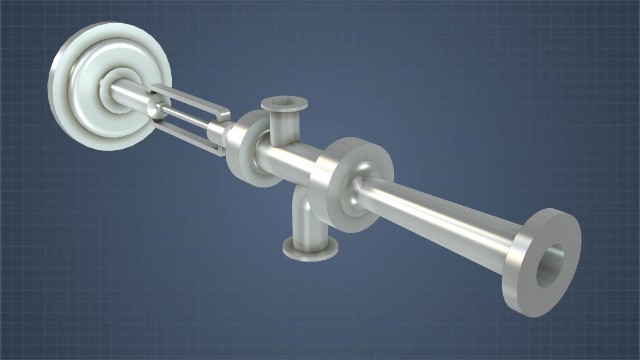

• List the main objectives of a paper or board machine dryer section • Identify and describe the purpose of dryer cans, dryer felts, dryer hoods, drive sections, and steam groups in a dryer section • Explain how thermocompressor steam systems and cascade steam systems allow steam to be reused in dryer sections • Identify and describe the components of a thermocompressor • Identify and describe steam and condensate flows in a typical thermocompressor steam system • Identify and describe safety hazards and safety guidelines related to paper machine thermocompressor steam systems

Specs

Frequently Asked Questions

What is a steam group on a paper or board machine?

What is a thermocompressor?

How does a thermocompressor like a valve?

Why is that thermocompressor steam systems can respond more quickly to production rate changes than cascade steam systems?

How do thermocompressor steam systems account for the decrease in drying rate that occurs as the sheet dries on a paper or board machine?

Sample Video Transcript

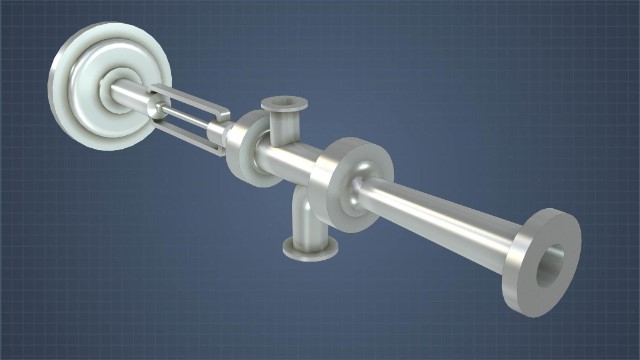

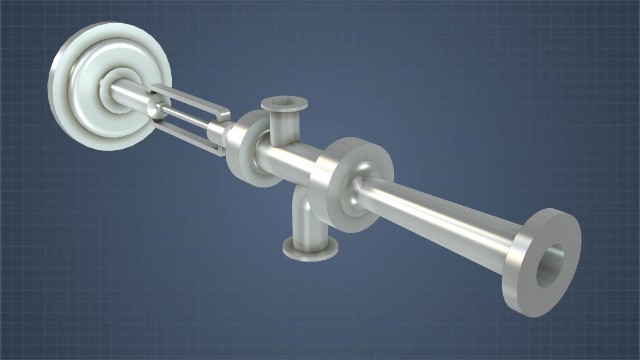

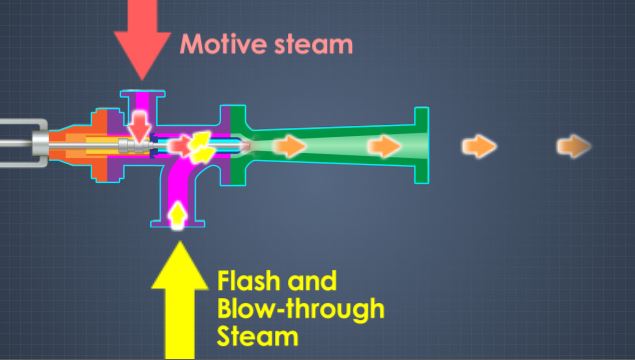

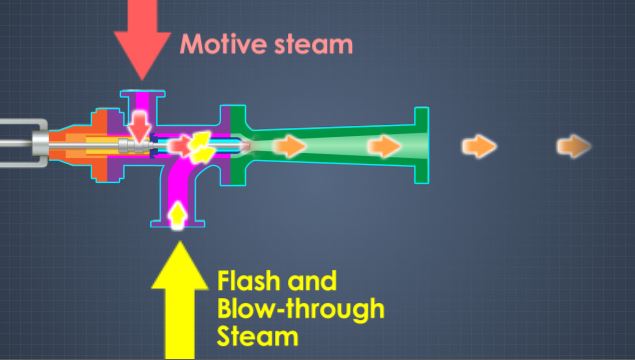

In a thermocompressor, the high pressure motive steam passes through the nozzle, which significantly increases its velocity and lowers the pressure at that point in the device. Steam from the condensate separator tank is pulled into this low pressure area. As the combined steam moves through the diffuser, the velocity decreases and the two steams come to thermodynamic equilibrium and an intermediate pressure steam emerges. The actuator moves the spindle toward or away from the nozzle opening to control the flow of motive steam through the thermocompressor nozzle. Therefore it controls the creation of the vacuum and the amount of flash and blow through steam that is pulled into the thermocompressor.