Shoe Presses – Tissue

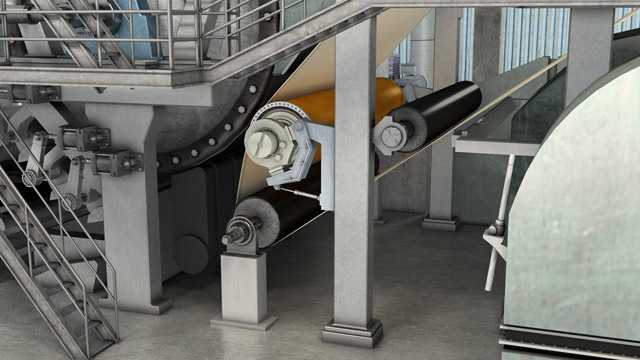

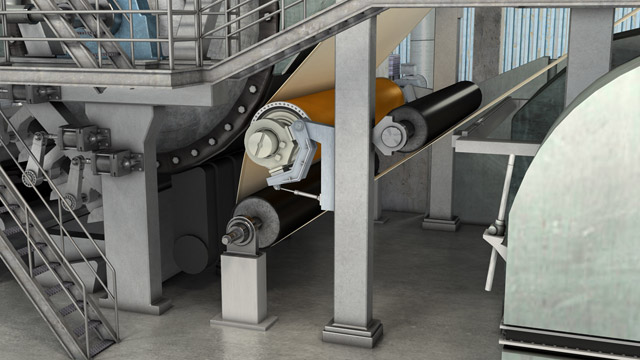

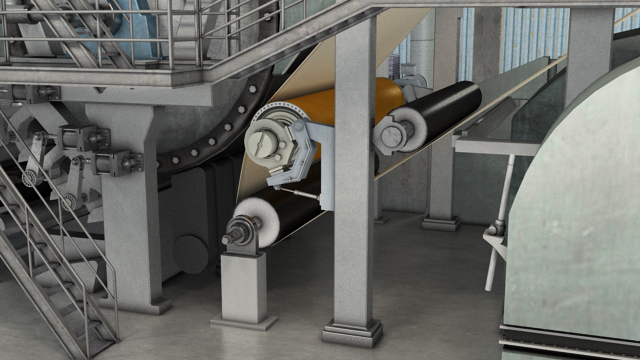

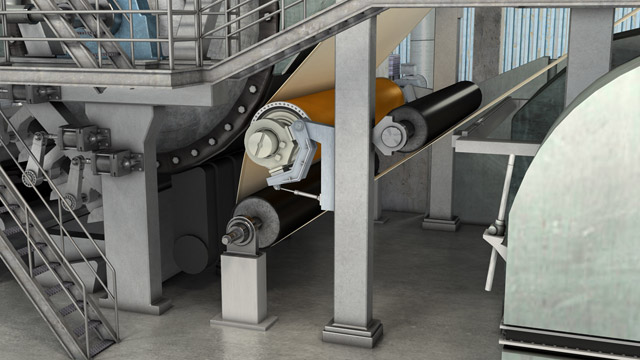

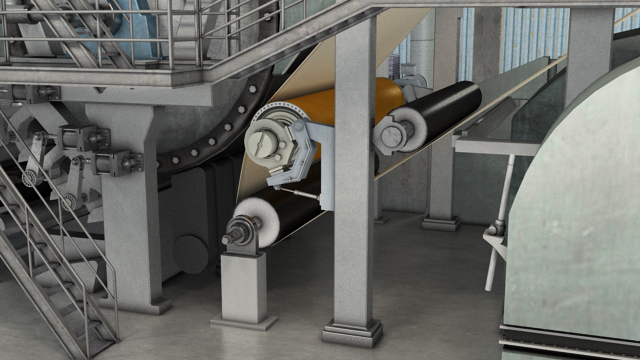

Shoe presses have been used in the production of paper and board for years, and have more recently been used in tissue manufacture. On tissue machines, they can replace the suction pressure roll, or they can be used in other sheet transfer locations. Shoe presses offer a significantly longer nip width and dwell time than conventional suction pressure rolls. Benefits include increased bulk, higher dryness after pressing (PPRC), and improved cross-machine direction (CD) moisture profiles. These can reduce fiber costs, reduce drying energy requirements or increase machine speeds, and improve sheet quality and machine runnability.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

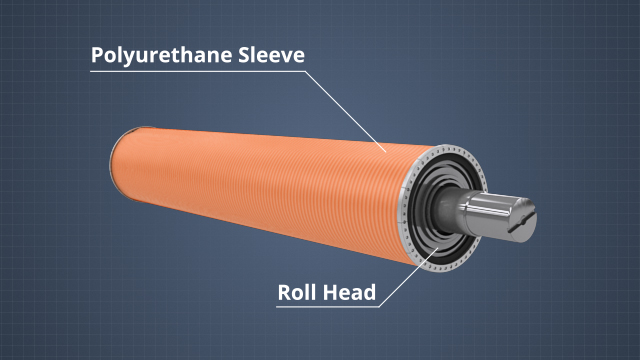

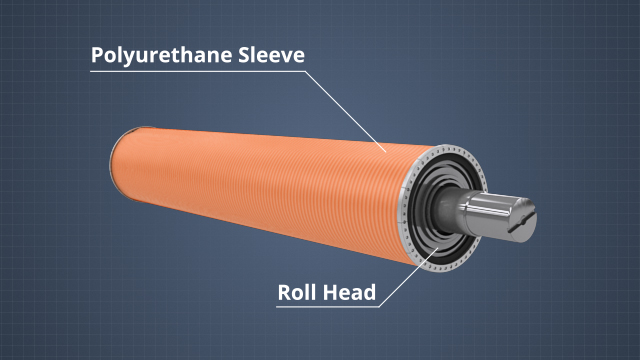

Describe the major difference between a shoe press and a conventional suction pressure roll Identify the two functions of a suction pressure roll on a tissue machine List the benefits of shoe presses on tissue machines Identify and describe the major components of a shoe press, including the stationary press beam, hydraulically-loaded shoe, sleeve or belt, roll heads and journals, and dedicated hydraulic system

Specs

Frequently Asked Questions

Where were shoe presses originally used?

Besides loading the press shoe, what are the other functions of the hydraulic fluid that is supplied to shoe presses?

Which components of a shoe press typically rotate during production?

What are the three main ways post pressure roll consistency (PPRC) can be increased on a tissue machine?

Why are the roll heads on some shoe presses designed to be moved toward the front or back?

Sample Video Transcript

A typical modern shoe press has the following major components: one, a stationary press beam, two, hydraulically-loaded press shoe, three, sleeve or belt, four, roll heads and journals, and five, hydraulic system. That stationary press beam is a cross machine structure on which the press shoe and its hydraulic loading elements are mounted. It must be designed to support the static loads as well as the offsetting hydraulic forces in the nip. The press shoe can be hard or soft and its dimensions and the resulting nip width varies.