Continuous Digesters – Vapor Phase

In a continuous digester, wood chips and liquor are continuously fed to, and withdrawn from, a pressure vessel. Continuous cooking offers some distinct advantages over batch cooking, including reduced space requirements, improved cooking control, and improved energy efficiency. Many variations of continuous digester equipment and process conditions have been used. Some digesters are hydraulically filled, while others utilize a vapor phase. This module covers the basic principles of operation of vapor phase continuous digesters.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Describe the advantages of continuous digesters

• Identify the purposes of a continuous digester chip feed system

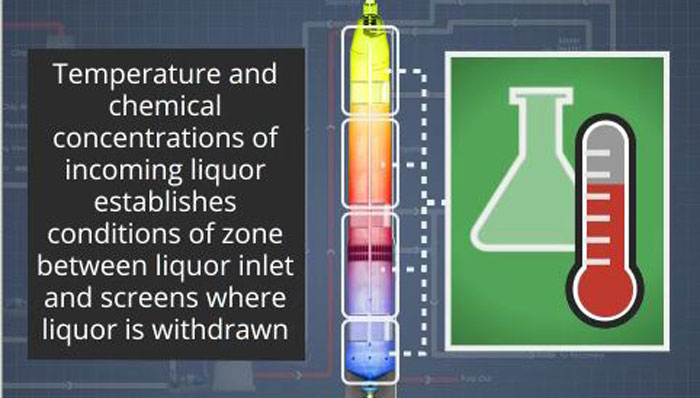

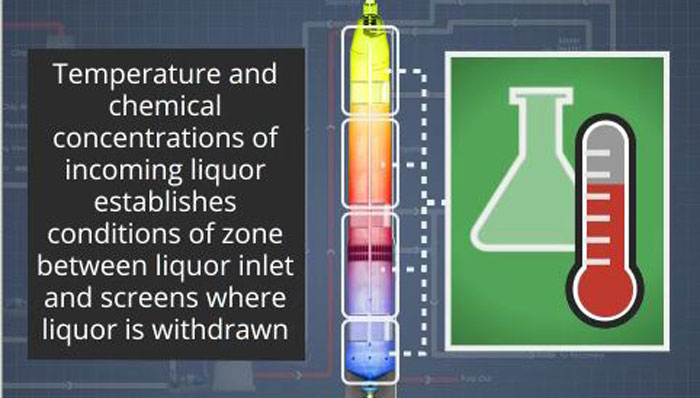

• Describe how process zones are established in a continuous digester

• Identify the benefits of a vapor phase continuous digester

• Describe the advantages of using an impregnation vessel

• Identify some of the guidelines which maximize the benefits of continuous cooking

Specs

Frequently Asked Questions

What is a vapor phase digester?

What are some of the goals of the chip feed system on a continuous digester?

What is one advantage of a vapor phase digester?

How are process zones established within a continuous digester?

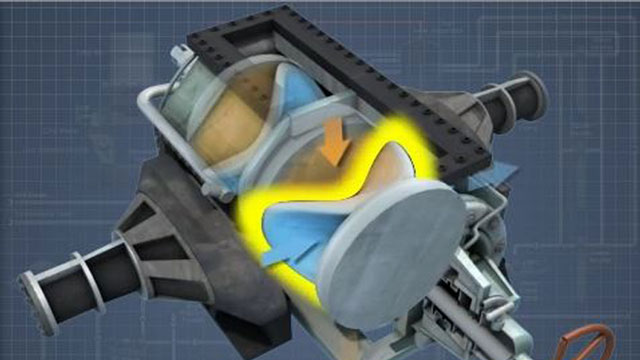

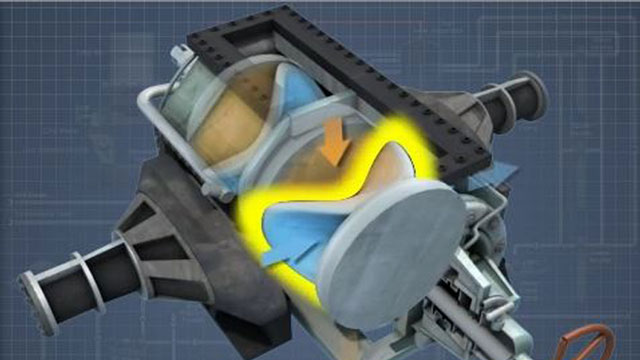

What job is performed by a top separator in a continuous digester?

Sample Video Transcript

In a vapor phased digester, the liquor level is maintained slightly below the chip level. The vapor space at the top is filled with steam, which condenses and heats the incoming chips. This system was developed to address problems with scaling, which occurred in some external liquor circulation heaters. Heating the chips directly with steam eliminates the need for the heating zone circulation heater. Which solves the liquor circulation and scaling issues. In addition to that, the use of direct steam heats the chips more quickly than hot liquor, and increases the rate of liquid penetration into the chips, which allows higher production rates.