Yankee Dryer Steam and Condensate Systems

The Yankee dryer is a large, steam-heated, pressure vessel that is used in the production of tissue grades. During production, high pressure steam is supplied to the inside of the dryer to heat the shell and dry the sheet, and the condensate that forms must then be removed. This course describes the steam distribution and condensate removal equipment found in a Yankee dryer. It then discusses how the steam pressure inside the dryer is controlled, how thermocompressors operate, and two common methods used to control the flows of steam and condensate through a Yankee dryer.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.

Course Details

Learning Objectives

• Describe the design of the Yankee dryer

• Describe steam distribution equipment and flows inside dryer

• Identify how condensate is removed from the dryer

• Describe pressure controls in and around the Yankee dryer

Specs

Frequently Asked Questions

What operating conditions affect the heat transfer from the dryer to the sheet?

What is blow-through steam?

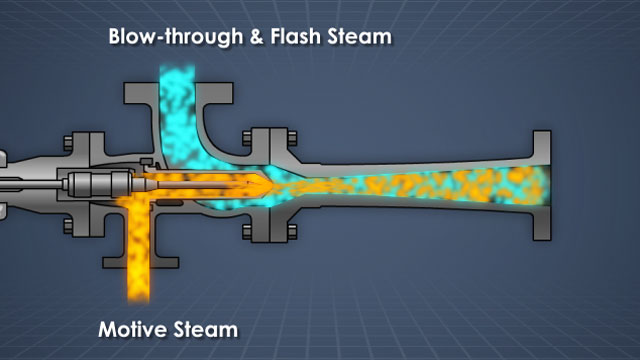

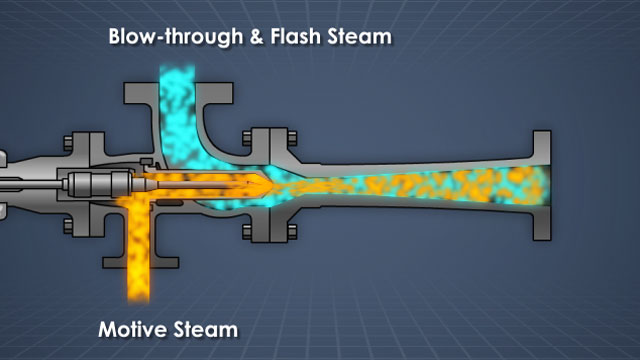

What is a thermocompressor?

How is condensate removal controlled?

How is dP controlled?

Sample Video Transcript

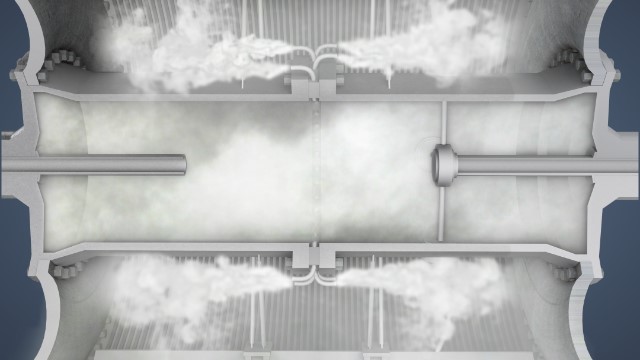

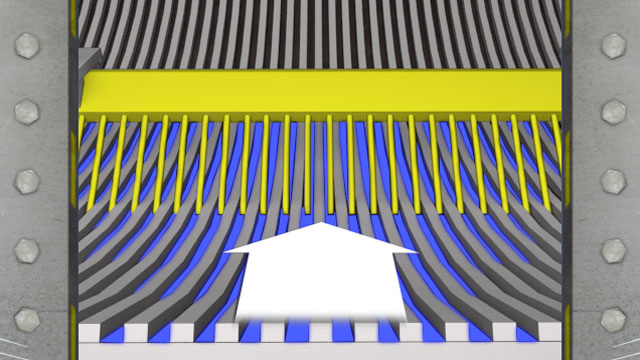

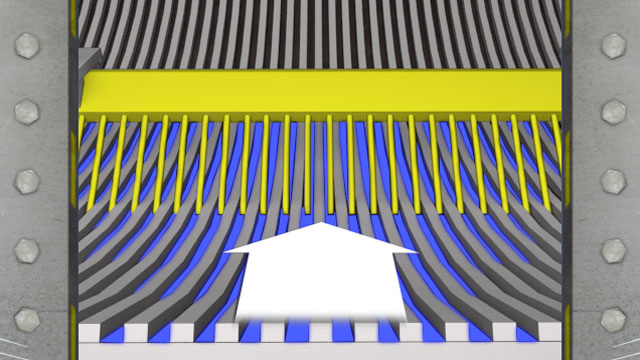

Inside the yankee, the steam condenses and transfers its heat to the shell. The resulting condensate must be removed at the same rate as it forms in order to maintain the efficient transfer of heat to the sheet. The condensate removal equipment includes the condensate headers, soda straws, riser pipes, and central steam collection pipe. The condensate headers receive condensate collected by soda straws in the grooves of the shell. The condensate is carried away from the headers by the riser pipes to the central steam collection pipe. The soda straws are thin pipes that extend from the condensate headers into the centers of the grooves inside the dryer shell. Because the pressure inside the dryer is higher than the pressure inside the condensate headers, the condensate plus some steam, flows up the straws into the headers.