July 30, 2025 3 min read

Industrial Safety: 10 Daily Workplace Safety Tips in Manufacturing

Industry:

Solution:

In manufacturing, safety isn’t optional. It is a necessary priority to achieve operational success. Every injury, near miss, and shutdown caused by a preventable hazard threatens more than just compliance. It jeopardizes workforce safety and wellbeing, production, employee morale, and a manufacturing plant’s bottom line.

In fact, nearly 40 percent of industrial workers say safety is discussed only after an incident has occurs further highlighting the urgent need for proactive safety habits and daily reinforcement.

What is Industrial Safety?

Industrial safety refers to the protocols and practices that protect workers, equipment, and infrastructure in high-risk industrial workplace environments. It’s the foundation for consistent output, workforce stability, and regulatory alignment. It means creating good daily safety habits that include identifying hazards, following protocols, and making sure that every employee whether a new employee or a veteran technician returns home safely. Occupational Safety and Health Administration (OSHA) standards may set the baseline, but true safety leaders go further, embedding risk awareness and prevention into every layer of the operation.

Why Industrial Safety Matters

Effective industrial safety practices help manufacturers reduce workplace injuries, avoid costly disruptions, and maintain compliance with OSHA regulations. Beyond the legal obligations, a strong workplace safety culture reduces workers’ compensation claims, improves retention, and increases employee confidence. A single incident such as laceration, fall, electrical shock, or more serious injury can result in production delays, regulatory fines, and long-term harm to both employees and the business.

By consistently applying safety protocols and training, manufacturers can shift from a reactive model to a proactive one and mitigate hazards before they escalate into workplace risks.

Examples of Industrial Safety Equipment

Industrial manufacturing settings require a wide range of personal protective equipment (PPE) and engineering controls to safeguard workers. Common safety equipment includes:

- Hard hats and safety helmets

- Safety goggles and face shields

- Cut-resistant gloves

- Hearing protection

- High-visibility vests and flame-resistant clothing

- Face shields

- Machine guards and lockout/tagout devices

- Masks and respirators for respiratory protection

- Slip-resistant footwear

- Eye wash stations

- First aid kits

All equipment must be regularly inspected, properly fitted, and used according to manufacturer and OSHA guidelines to reduce injury and exposure risk.

Understanding Key Safety Concepts

There are a few core concepts that shape effective safety programs in manufacturing.

1. Understand the difference between a hazard and a risk

A hazard is a potential source of harm such as a chemical leak or unguarded machine. Risk is the likelihood that harm may occur from that hazard. Recognizing both is key to prioritizing preventive actions.

2. Understand your responsibilities under OSHA

OSHA sets national safety standards that all manufacturers must follow. Supervisors, safety leads, and frontline employees each play a role in maintaining these standards through proper training, consistent practices, and accurate recordkeeping. From OSHA 300 logs to incident reports and safety audits, documentation is needed to maintain compliance and continuous improvement.

3. Recognize the purpose of PPE

PPE such as gloves, face shields, and hearing protection is your last line of defense. But it only works when selected properly, worn correctly, and maintained consistently.

4. Learn your facility’s emergency protocols

From emergency action plans and lockout/tagout procedures to chemical handling and machine guarding, every facility must have standard operating procedures (SOPs) to reduce risk. Following the SOPs is essential.

5. Build safety awareness into daily tasks

Safety isn’t something to check off once a year. It requires daily attention, hazard recognition, and communication, especially in fast-moving or high-risk areas of the plant.

6. Assess where your team is on the safety culture curve.

The DuPont Bradley Curve is a framework that outlines how safety performance improves as organizations move from reactive to interdependent safety cultures. This is a culture where employees look out for one another and take responsibility for safety for everyone in the workplace. Moving up the curve requires implementing a culture where employees feel safe to speak up. The National Academies reinforces the value of this approach and notes that “all people are susceptible to both physical and psychological harm.” Increasing safety awareness across the workforce encourages open communication, where employees feel safe reporting hazards or reporting concerns without fear of retaliation. Employees take responsibility for safety outcomes and organizational trust grows.

With a strong understanding of key safety concepts, teams are better equipped to take consistent action on the manufacturing plant floor. The following ten safety practices are designed to help frontline manufacturing leaders and plant teams reduce injuries, improve productivity, and build a culture where safety is a focus of every shift.

Award-Winning Safety Courses

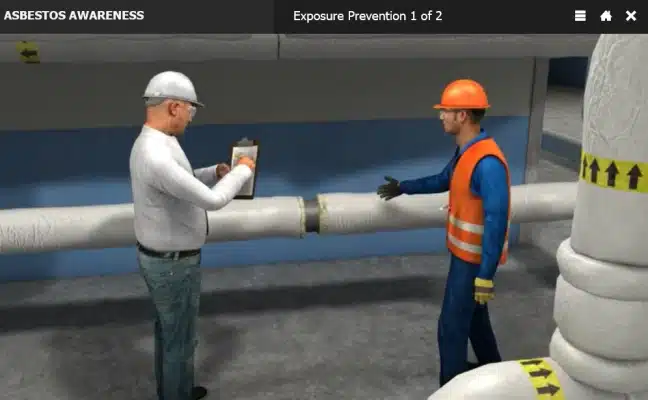

Explore 400+ courses with 3D animations and live action footage.

Download the Catalog

10 Easy Ways to Improve Safety in a Manufacturing Work Environment

Here are 10 quick and easy tips for a safer manufacturing workplace.

1. Inform Supervisors of Unsafe Conditions

If you see something that could potentially hurt someone, remove the object or clean the area if you can do so safely. Otherwise, inform your supervisor. Supervisors are legally required to maintain a safe working environment and must take action when notified. Understanding how to recognize and communicate hazards is a key component of safety awareness, as covered in job hazard analysis training.

2. Use Equipment, Machines, and Tools Properly

Misusing tools and machines are the most prevalent cause of workplace injuries. When using equipment, make sure that you are using each piece of equipment for its intended purpose and are using it correctly. Regularly clean and inspect equipment to ensure that it is safe. These best practices are commonly reinforced in Hand and Power Tools Safety training.

3. Wear Safety Equipment (PPE)

Whether operating machinery or handling spills and debris, workers should always wear the appropriate PPE for the task. PPE must be properly selected, correctly worn, and free of damage to significantly reduce the risk of injury. These practices should be emphasized in PPE training.

4. Prevent Slips and Trips

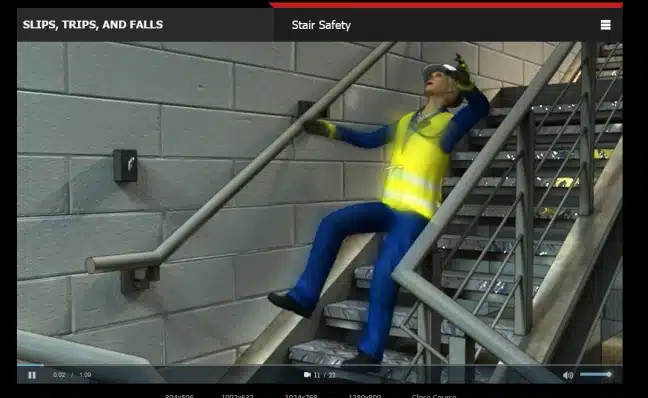

As the most prevalent cause of occupational injuries, it is vital to make sure that aisles are clear and spills are cleaned to prevent employees from tripping or slipping. When working with liquids, use drip pans and splash guards to contain runoff. Inspect the floor for loose boards, holes, or protruding nails, and repair damaged surfaces promptly. In areas that are prone to moisture or buildup, install anti-slip flooring to reduce risk. These preventive measures are covered in slips, trips, and falls training.

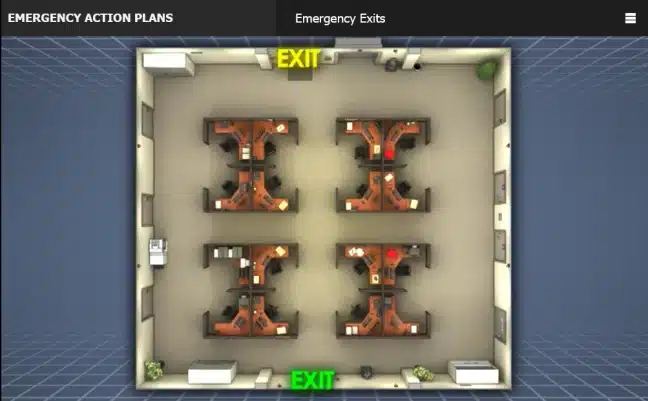

5. Keep Work Areas and Emergency Exits Clear

Make sure to remove any clutter blocking emergency exits, equipment shutoffs, and areas that you are working. A cluttered work area can lead to not having enough space to use tools and pick up heavy objects properly. Furthermore, if an exit is obstructed, employees may not be able to quickly escape if an emergency occurs. Placing equipment in proper storage areas after use helps keep the work area and emergency exits clear. These are all important topics to cover in emergency action plan training.

6. Eliminate Fire Hazards

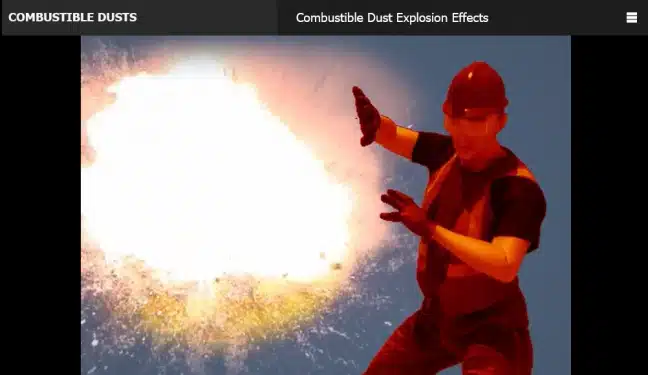

When using combustible materials in the work environment, only keep the amount you need for the task at hand. Store the chemical in an assigned safe storage area away from sources of ignition when not in use. Also, store combustible waste in metal receptacles and dispose of it daily. This hazard awareness can be increased by assigning fire safety training, fire extinguisher training, and combustible dusts training.

7. Avoid Tracking Hazardous Materials

To help prevent hazardous materials from being accidentally tracked into other areas, make sure that work area mats are maintained and kept clean. Prevent cross-contamination by using different cleaning materials-such as mops-for various spills, and change clothes if you spill toxic materials on them. If you work with hazardous materials, avoid wearing your work clothes home. Implementing industrial hygiene training is important for preventing hazardous materials accidents.

8. Prevent Objects from Falling

Falling objects can cause serious injuries and damage to equipment and materials. Use safeguards such as toe boards, toe rails, and safety nets in elevated areas. Always stack boxes evenly and place heavier items on lower shelves to improve stability. Keep all stacked materials clear of aisles and work zones to prevent collisions. Proper forklift operation and load handling also play a key role in preventing product damage and tip-overs. These topics are covered in Forklifts: Reducing Product Damage training.

9. Use Correct Posture when Lifting

Back injuries are one of the most common workplace injuries in manufacturing environments. To reduce your risk, keep your back straight, lift with your legs, and avoid stooping or twisting your body. Use mechanical aids such as forklifts, wheelbarrows, or conveyor systems to minimize strain. These best practices are reinforced in Back Injury Prevention training.

10. Take Work Breaks From Time to Time

Heat stress isn’t limited to outdoor environments. High temperatures from manufacturing plant machinery, poor ventilation, and physical exertion can quickly lead to worker fatigue, dehydration, and reduced alertness. When workers are overheated or overtired, their ability to recognize hazards declines and it puts themselves and others at risk. Regular breaks, hydration, and cool-down periods are essential for maintaining focus and preventing heat-related incidents. These strategies are covered in the indoor heat stress training course.

How Vector Solutions Supports Safer Manufacturing Operations

Safety is a key factor in a manufacturing team’s wellbeing, operational efficiency, and compliance. From back injuries and slips to heat stress and equipment hazards, manufacturers face daily risks that require proactive, informed training.

At Vector Solutions, we’re committed to supporting industrial manufacturers. Our OSHA-aligned safety training courses are built by experts and designed for real-world industrial environments. The training is interactive and delivered in engaging 3D formats to support today’s workforce and reinforce safe habits on the job.

For a safer workplace and better safety training, request a demo today to see how Vector Solutions can help.