May 2, 2017 3 min read

Is there a difference between a JHA and a JSA?

Industry:

Solution:

JSA stands for “Job Safety Analysis” while JHA stands for “Job Hazard Analysis.” Most safety professionals use the terms JSA and JHA interchangeably to describe a technique for improving worker safety when completing hazardous tasks, so is there really a difference between the two?

What is a Job Safety Analysis or Job Hazard Analysis?

Both a JSA and JHA are a process to identify hazards within jobs and tasks and implement safety controls to reduce the risk of the potential hazards. There are four steps to conducting a JSA or JHA that should be followed to reap the benefits of a JSA.

The components of a JHA and JSA

Both a job safety analysis and a job hazard analysis contain three specific components:

- Looking at the steps that make up a job.

- Identifying the hazards at each step.

- Finding safety measures to avoid these risks.

In addition, both a JSA and JHA include a risk assessment to evaluate potential hazards.

A risk assessment generally reviews the severity and probability of potential hazards. Most safety professionals utilize risk matrix calculations to assess and prioritize these hazards risks. We’ve put together a guide on risk matrix calculations and hazard assessment that you can download to try for yourself.

Risk Matrix Guide

Get the Guide

Ultimately, the processes, end goals, and results of a JSA and JHA are the same, so it makes sense that these terms are frequently used interchangeably. At IndustrySafe, we don’t see that there’s any difference between a JSA or JHA. If you feel differently, though, don’t be afraid to share your thoughts and opinions on the subject!

Does OSHA require a JSA?

Several components of the OSHA regulations require a hazard assessment to decide what personal protective equipment may be needed to control the hazards on a job. Additionally, a certification that hazard assessment has been performed must be kept on record.

However, OSHA does not specifically state that a JSA/JHA is required as part of this hazard assessment. Instead, it’s important to know that performing and documenting a JHA or JSA will assist you in complying with the hazard assessment requirements.

In addition, OSHA strongly recommends and encourages the use of JSAs and JHAs as evidenced by the training materials developed by OSHA. For example, see OSHA’s Job Hazard Analysis handbook, as well as this Job Safety Analysis etool developed by OSHA for the Oil and Gas Industry.

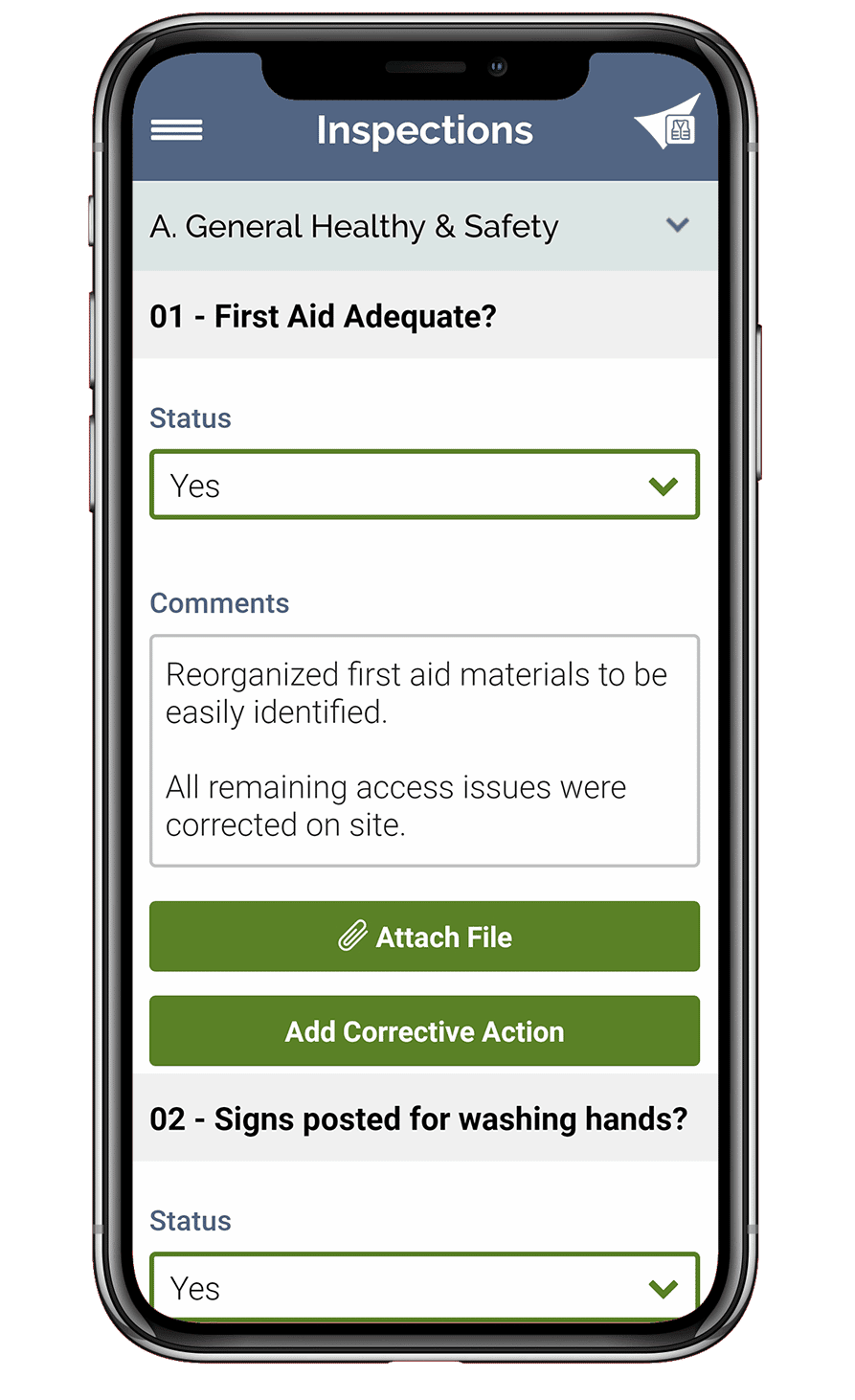

Vector EHS Management Software empowers organizations – from global leaders to local businesses – to improve workplace safety and comply with environmental, health, and safety regulations.

Learn more about how our software can save you valuable time and effort in recording, tracking, and analyzing your EHS activities.

Learn more about how we can help:

- Incident Management Software →

- EHS Inspection Software →

- Key Safety Metrics Dashboard →

- Learning Management System (LMS) and Online Training Courses →

- Mobile Risk Communication Platform

Download our EHS Management Software Buyer’s Guide.

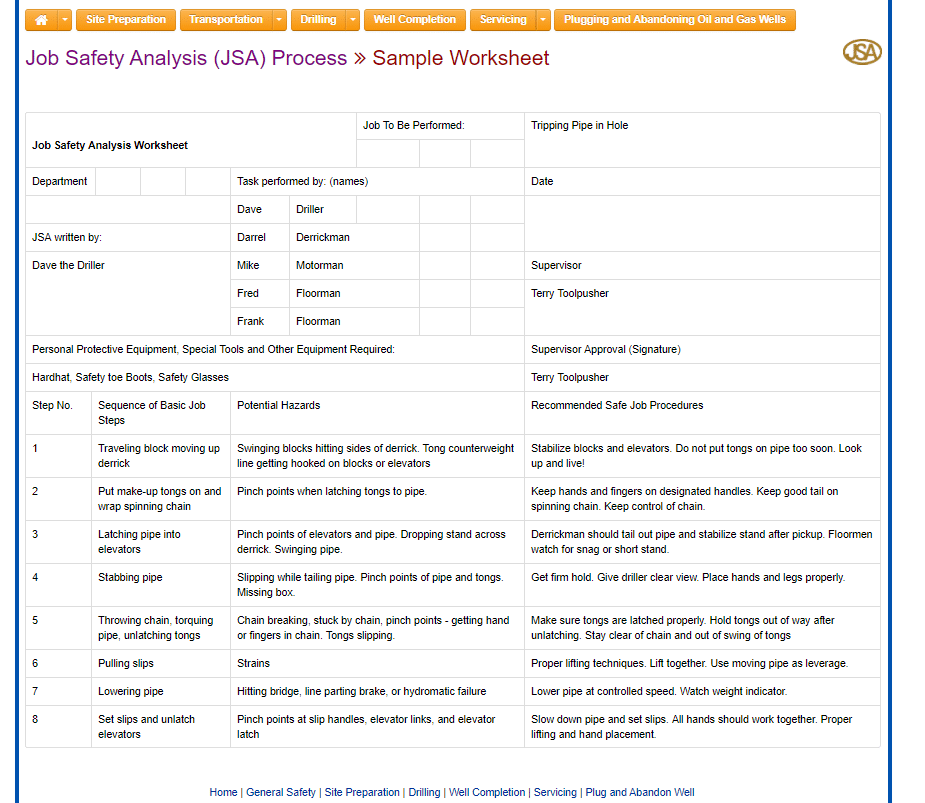

What does a JSA Template look like?

There are many different examples of JSA Templates. Most JSA Templates include the following:

- The job and associated tasks or steps that make up the job;

- the identified hazards for each task/step;

- the hazard risk assessment;

- the hazard controls (such as PPE, training, etc);

- and the mitigated risk assessment after the use of controls.

Organizations may also include on the template the date/time of the JSA history, as well as sign-off and approvals from key individuals of the JSA. A sample worksheet/template from OSHA is below. At Vector EHS Management software, we utilize a configurable template that includes all of these fields and more.

You can view an interactive version of a Vector EHS Job Safety Analysis template by signing up for a demo of our Software and navigating to our job hazard analysis software module. Contact us for more information about Vector EHS’s JSA software.